315KW 2-Stage Rotary Screw Air Compressor

Application

315kw 2-stage rotary screw air compressor is widely used in all kinds of industries around the world, including machinery, medicine, textile, electronics, automotive, construction, and military.

| Model | Power KW | Discharge pressure MPa | FAD m³/min | Noise Db(A) | Outlet pipe diameter ('') | Dimension L*W*H mm | Weight kg | Oil consumption L | ||

| 315 | 0.8 | 67.0 | 80±2 | DN125 | 4100 | 2100 | 2150 | 200 | ||

| 1.0 | 63.0 | |||||||||

| 1.3 | 51.0 | |||||||||

Components of 315KW 2-Stage Rotary Screw Air Compressor

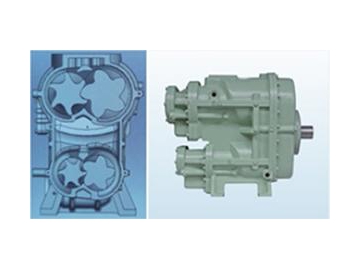

Screw Air Compressor Air-End

Designed with large rotors and low rotating speed, our screw air compressor air-end has two independent compression units. Its rotor introduces the latest design – UV patented rotor profile design, and undergoes two dozens of processes, whose accuracy is strictly controlled, so the precision, reliability, as well as the efficiency of rotor motor could all be guaranteed.

Screw Air Compressor Rotor

Screw air compressor's air-end rotor is directly connected with its motor, allowing a smaller noise;

Meanwhile, efficient bearings, like, cylinder roller bearing and angular contact ball bearing, are utilized, which could be used for more than 100,000 hours.

Screw Air Compressor Motor

Motors of our screw air compressor are all produced by professional motor manufacturer, and all of them will undergo strict testing before being delivered to customers, so their quality are well guaranteed. And local treatment is carried out for our variable frequency motor and our plateau motor. Our four pole motor features low rotation speed and high reliability.

Our motor is always coupled with heavy duty SKY bearings, and we installed oil fillers on both sides of bearing housing, providing much convenience for maintenance and repair.

In addition, since our motor is qualified for IP55 ingress protection, both dusts and water could be blocked from our motor, so a long service life of our motor could be ensured.

Screw Air Compressor's Structure

Since the hot chamber and the cold chamber of our rotary screw air compressor is separated, a good thermal dissipation effect is well ensured. Meanwhile, all the components of our air compressor work in cold chamber, so they could be used for long period of time.

Our rotary screw air compressor is specially designed as an integral structure of mechanic and electric, which reaped a national patent. Thus, both an easy delivery and installation could be ensured.

The air compressor is separated into cold chamber and hot chamber, both chambers work independently with no interference. Meanwhile, its inner space is enlarged, which helps to realize scientific air circulation, sufficient cooling for components and prolonged service life.

In order to reduce working noise, our compressor is designed as an all-sealed structure with detachable cabinet, together with the installation of high-quality sound absorbing foam sponge. In this way, both an easier cleaning and eco-friendliness could be guaranteed.

Oil-Air Separator's Installation Structure

Aftercooler and oil-air separator are assembled together without any installation of pipes, which largely saves the space, prevents leakage, and reduces the installation cost. Meanwhile, since a shorter distance is designed between aftercooler and oil-air separator, the fluid flows in a more reasonable direction and a higher separation efficiency between oil and water is realized.

Lube-Oil Injection for First-Stage Air Compression and Second-Stage Air Compression

Our air compressor introduces an atomized injection of lube-oil for both first-stage and second-stage compression, allowing a high cooling efficiency and low lube-oil consumption. Meanwhile, since our compressor has no intercooler, both the consumption and maintenance cost could be reduced.

Shutoff and Vent Combination Valve

In order to activate large-size air compressor in light loading, to reduce the impact towards power grid, and to prolong its motor's service life, we installed shutoff and vent combination valve, featuring simple structure, which helps to prevent oil leak and start failure.

New Thermostatic Control and Oil Filter Combination Valve

Thermostatic control valve and oil filler valve are combined together as an integral structure, which helps to ensure a concise piping system, a reduced oil leak points, smaller malfunction rate, decreased pressure lose, and better energy conservation. Meanwhile, the combination valve's introduction also well prevents pipe bursting and oil leakage, always familiar when oil filter base and thermostatic control valve are installed independently.

Solenoid Valve

ODF solenoid valve, imported from Italy, is introduced.

Solenoid valve's function:

Direct acting solenoid valve is adopted, which will be activated as soon as the power is connected, featuring safer and faster activation when compared with traditional pilot valve.

But please notify that only when the pressure arrives to 0.2bam, could the valve be started. So the controlling system connected with the valve will be more precise and timelier.

Electric element

All the electric elements for our rotary screw air compressor are purchased from SIEMENS from German, ET and other reliable brands.

Air-Inlet Controlling System

An air-inlet controlling system, latest design in the field, is adopted in our air compressor. It owns an integral design for air inlet, air displacement, and many other functions, which allows reduced controlling wires. Meanwhile, single-direction valve is mounted in our air inlet controlling system, so when the air supplying is stopped, the air-inlet valve will be automatically stopped as well. Thus, air's return will be blocked and oil leakage will be prevented.

With a combined controlling towards air inlet valve, intelligent controlling system, and pressure sensor, switch controlling system(ON/OFF), stepless capacity control system (60%-100%), and delayed start and stop device, as three air flow controlling methods, are all available in Jufeng, so different customer requirements could be satisfied.

Wearing Parts

Air filter: Nano-composite coating is introduced for our air filter, which allows zero air direction changing during filtering and zero pressure loss. When compared with traditional air filter, it possesses the character of higher filtering accuracy and longer service life.

Oil filter: Durable filtering materials are adopted, which enables a precise filtering and stable operation for our air compressors.

Oil-air separator: Concise designed oil-air separator and oil return device are used together for low oil content during free air delivery – no higher than 2PPM.

Description

After first-stage compression, oil injection will be introduced forcefully to cool the suction temperature for second-stage compression, to compress air at a constant pressure, and to reduce the compress power.

Interstage pressure will be set by adjusting pressure ratio, also known as compression ratio, so the compression ratios in each stage will all be quite smaller than that of single-stage compression. Meanwhile, the leakage amount during different rotors is effectively reduced, while the volumetric efficiency and the adiabatic efficiency are largely improved, thus allowing an improved gas production rate. In addition, when work in same power, two stage air compressor will have a 15% higher gas output, and a 15% energy saving than one-stage air compressor.

Jufeng is an industrial air compressor manufacturer and mainly offers rotary screw air compressors. Besides the 315KW 2-stage screw air compressor, our 2-stage air compressors are available from 15KW to 315KW. Equipped with complete manufacturing and assembly lines, we offer quality rotary screw air compressor and compressed air treatment equipment for customers.