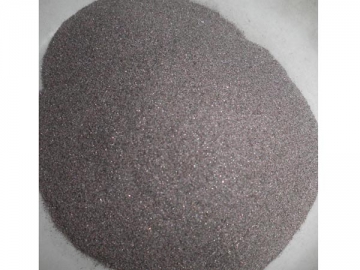

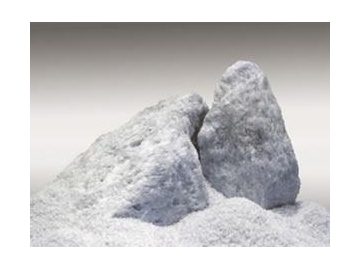

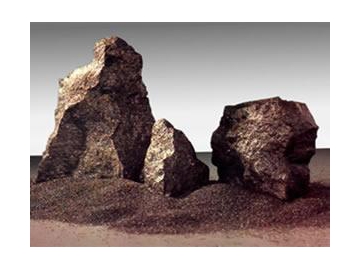

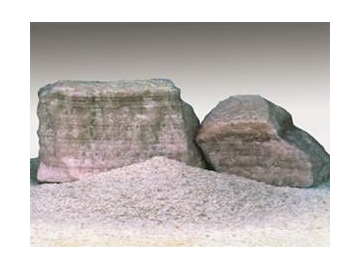

Brown Fused Alumina

Brown Fused Alumina

Brown fused alumina is produced from high quality bauxite . This process is conducted via the 3500 KVA electric arc furnace ata temperature higher than 2200℃.The process of products :bauxite broken intocrushing machine --- elevating-- --sizing ---magnetic separator ---finesieve ---water washing (acid washing )---package (25kg/pp bag or paper bag ,40 bags / ton bag or pallet)

Our brown fused alumina covers two primary lines. The F type is mainly targeted at consolidating abrasive materials and sand blasting. The P type is designed for coating abrasives. Raw materials are mainly acquired from GuizhouLuQian Alumina Fusing Factory. Currently, this is the only known producer in northern

Specifications

Grains Types and Grades | |||||

Usage | For vitrified wheels | For belts | For sheets | For Organic Wheels | For Blasting |

Type &Grade | A | A-P 1 | A-P 2 | A-B | A-S |

Size | F: 4#-80# 90#-150# 180#-240# P: 8#-80# 100#-150# 180#-220# W: 1#-63# | ||||

Chemical composition | |||||

GB/T 2478-1996 |

| ||||

Type & Grade | Grit | Chemical Composition(%,by weight) | |||

AL2O3 | TiO2 | CaO | |||

A | F4~F80 | 95.0~97.5 | 1.5~3.8 | ≤ 0.45 | 0.25 |

F90~F150 | 94.0~97.5 | ||||

F180~F220 | 93.0~97.5 | ||||

F220 finer | ≥ 92.0 | ||||

A-P 1 | P12~P80 | 95.0~97.5 | 1.5~3.8 | ≤ 0.45 | 0.25 |

P100~P150 | 94.0~97.5 | ||||

P180~P220 | 93.0~97.5 | ||||

P220 finner | ≥ 92.0 | ||||

A-B | F4~F80 | ≥ 93.0 | 1.5~4.2 |

| 0.28 |

F90~F220 | ≥ 91.0 | ||||

F220 finner | ≥ 90.0 | ≤ 4.5 | |||

A-P 2 | P8~P80 | ≥ 93.0 | 1.5~4.5 |

|

|

P100~P220 | ≥ 91.0 | ||||

P220 finner | ≥ 90.0 | ≤ 4.5 | |||

A-S | 16~220 | ≥ 92.0 | ≤ 4.2 |

|

|

Item | 95 | 96 | 97 |

Al2O3 | ≥95% | ≥96% | ≥97% |

SiO2 | ≤1.2% | ≤1.0% | ≤0.8% |

TiO2 | ≤3.2% | ≤3.0% | ≤2.0% |

Fe2O3 | ≤0.3% | ≤0.2% | ≤0.2% |

CaO MgO | ≤0.6% | ≤0.5% | ≤0.4% |

Real Density | ≥3.9 g/cm3 | ||

Moh's Hardness | 9.0 | ||

Micro Hardness | 2000-2200KG/MM2 | ||

Coarseness | 8-5MM, 5-3MM, 3-1MM, 1-0MM | ||

16# 24# 30# 36# 46# 60# 70# 80# 90# 100# 120# | |||

Fines | 180F 200F 240F 325F (Fe2O3 ≤0.50%) | ||

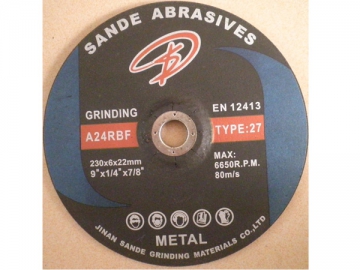

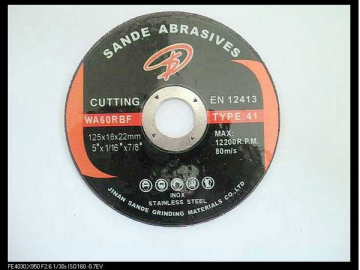

Brown fused alumina of P type is commonly used for make ceramic grinding wheel, grinding stone, sand paper, sand belt, polish wax, abrasive paste, etc. ItsF type can act as a sandblasting abrasive and is commonly used to decontaminate, remove dust, and prevent corrosion for select work pieces. Refractorymaterial: Mainly used for abrasion and high temperature resiatant, inoxidizableaggregate and filling of shaped and monolithic refractory in steel metallurgy,various industrial stoves, electric furnace etc. In addition, the alumina can be used for construction , ideal for airports, chemical factories, and other similar locations. It is also the ideal candidate for precision casting of materials such as stainless steel and aluminum.

According to function, our alumina falls into five major categories including A, A-P 1, A-P 2, A-B, and A-S. Type A is used for ceramic abrasive, A-P 1 is used for abrasive belt, A-P 2 is utilized for coated abrasive, A-B is used for organic abrasive, and A-S is designed for sand-blast polishing. In addition, our brown fused alumina can be utilized with a water jet dissector or other similar cutting systems to directly grind high-tensile metals such as cast iron, hard bronze, and annealed malleable iron. Apart from being used for manufacturing abrasive tools, it can also be used to produce high grade fireproof material.