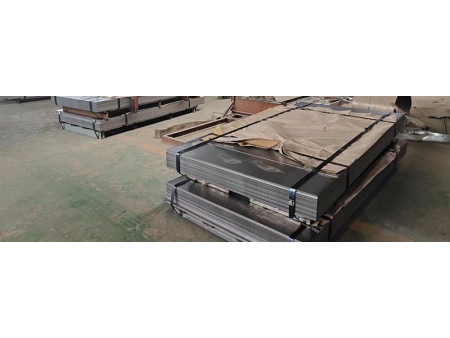

Hot Rolled Coil

In metalworking, rolling is a metal forming process through which metal stock is passed through one or more pairs of rolls to reduce the thickness and make the thickness uniform. Rolling is classified according to the temperature of the metal being rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling.

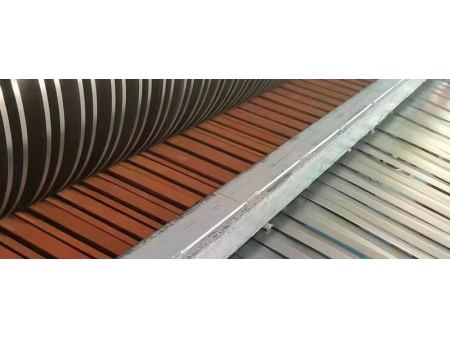

We supply customers with a variety of hot rolled coils that are made from premium aluminum alloy, rather than pure aluminum. This metal coil comes in 3 primary series: the 5-series, 6-series and 7-series aluminum alloy coils.

Available Types

1.

The 5-series aluminum alloy is among the most commonly used aluminum alloys and contains 3-5% magnesium, a major element in the alloy. It is also referred to as an aluminum magnesium alloy.

Applications

Hot rolled coils made using this alloy are commonly used in ship building, airplanes, automobiles, cooling devices, television towers, drilling equipment, transportation equipment and more.

2.

The 6-series aluminum alloy, represented by 6061, primarily contains magnesium and silicon.

Application

6061 aluminum coils are corrosion resistant and oxidation resistant, making them suitable for applications that require a certain level of mechanical strength, weldability and corrosion resistance, such as truck manufacturing, construction, trolley busses, furniture, machinery parts, precision processing and more.

3.

The 7-series aluminum alloy, represented by the 7075 hot rolled coil mainly contains zinc and is primarily an aviation alloy.

Features

1). High Hardness: The aluminum-zinc-magnesium-copper alloy is a super hard allow suited best for hot rolling, making it applicable for airplane manufacturing.

2). High Thermal Conductivity: With a high thermal conductivity, the 7075 alloy can increase processing efficiency and shorten the circle time.

3). High Abrasion and Corrosion Resistance

4). Anti-Distortion: By eliminating stress and deformation, we enable the 7075 hot rolled coil to be resistant to shape distortion. Large 7075 aluminum alloy sheets with a large thickness will undergo ultrasonic detection to avoid sand holes and other impurities.

Applications

Given the above features, the 7075 aluminum coil is suitable for applications requiring materials with a high mechanical strength and corrosion resistance. It can be used for mold making. Currently, all 7-series aluminum alloys are imported.