QT18-20 Automatic Block Making Machine

For customers who are looking for an upscale block making machine to ramp up your production, model QT18-20 might be the equipment of choice. Amended slightly by adding high-precision configurations, the block making machine can make very good automated block production line.

High efficiency, great productivity, and a big vibratory table have made our fly ash brick making machine stand out from the competition. Built with the latest industry-leading technologies, the brick machine houses many desirable features, such as the airbag compensation, multi-source vibration with adjustable amplitude, and fast mold change system. These features ensure high production efficiency and minimized energy consumption. The resultant concrete block has high density, strength, and uniform height.

Benefits of Automated Block Making Machine

1. Designed for all weather conditions

2. High-efficiency design cuts down energy consumption by 30%

3. Fast mold change features saves 50% time replacing molds.

4. Air-bag compensation ensures high stability, durability during the concrete block manufacturing process.

Features of Automated Block Making Machine

1. Framework

Made of high-strength steel, the framework of our automated block making machine is a rigid welded structure.

2. Guide Post or Guide Column

Ultra-strong steel is selected to construct each column with chrome plating for high wear-resistance and torsional strength.

3. Tamper Head or Compression Plate

Operating under the combined electrical, hydraulic, and mechanical system, the tamper head travels down along the guide post to compact the concrete mix in the mold. All the molds are supported by one common plate to facilitate block height control. The resultant finished block height can be consistent.

4. Feeding System

Equipped with sensors and proportional valves, the hydraulic feeding system of the automatic block making machine comes with an oscillating hopper that creates strong centrifugal forces to discharge the material and prevents arching or bridging. Placement of concrete mix is done fast, which suits the machine for manufacturing perforated bricks.

5. Vibratory Device

Made with patented technology, the vibratory system offers up to 20 different amplitude levels.

6. Control System

All key components of the control system are of Japanese Fuji brand. The control program is designed to meet specific production needs. Without any particular training, users can operate the control system easily and with little effort. Spacious storage allows for system upgrade.

7. Material Storage Device

Supply of concrete material is controlled by a computer, which is not affected by external factors or internal material stress. This ensures consistent material supply which ultimately guarantees that the finished concrete blocks have uniform specifications.

| Brick Specifications | BrickSamples | pcs/mold | pcs/h | pcs/8h | 1 year (300 days) |

| Concrete Blocks 390×190×190mm 71 pcs/m3 | 3 | 398 | 3184 | 13466 | |

| Concrete Blocks 390×100×190mm 135 pcs/m3 | 6 | 597 | 4780 | 10623 | |

| Dutch Bricks 200×100×60mm 50 pcs/m2 | 10 | 1394 | 11155 | 66931 | |

| Dog-Bone Pavers 200×165×60mm 30 pcs/m2 | 6 | 796 | 6374 | 63112 | |

| Zigzag Pavers 225×112.5×60mm 40pcs/m2 | 9 | 1195 | 9561 | 72619 | |

| Perforated Bricks 240x115x90 402pcs/m3 | 10 | 1300 | 10000 | 2.9 millionpcs | |

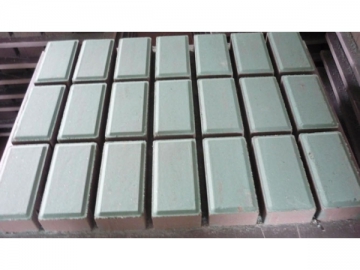

| Solid Bricks 240x115x53 683pcs/m3 | 20 | 2500 | 20000 | 5 million pcs |

| Dimension | 7500×5800×2900(mm) |

| Size of Pallet | 1350×1400×30(Bamboo Plywood) |

| Weight | 15100kg |

| Vibration Frequency | 50-90Hz |

| Maximum Excitation Force | 200KN |

| Molding Cycle | 15-20S |

| Installed Capacity | 85KW |