Elbow Hot Forming Machine

The elbow hot forming machine adopts hydraulic cylinder and intermediate-frequency heating. Elbow making machines using coal stove heating and natural gas heating are also available.

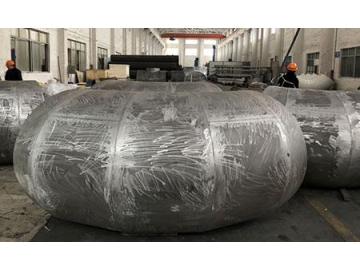

This hot forming machine is used for making carbon steel elbows and alloy steel elbows. The finished elbows are available with the diameter ranging from 21mm to 1620mm and the wall thickness from 3mm to 120mm.

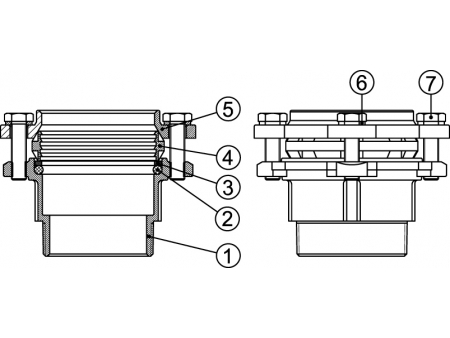

Our elbow hot forming machine consists of the following parts: base, master cylinder support plate (including master cylinder), mobile push plate, front support plate, semi-automatic feeding mechanism, IF coil adjustment bracket (including IF heating coil), IF power supply, and electrical control system.

Specifications of several common elbow hot forming machines are listed in the following table. In addition to the models listed in the table, we can also produce elbow forming machines according to customer requirements.

| Model | | | | | | | |

| Processing range | 1"~6" | 3"~12" | 8"~24" | 16"~30" | 20"~36" | 30"~48" | 32"~56" |

| Max. wall thickness | Sch40 | ||||||

| Max. pressure | 31.5MPa | ||||||

| Working pressure | 25MPa | ||||||

| Working speed | 0~1000mm/min | ||||||

| Return speed | 1500~2000mm/min | ||||||

| Cylinder diameter | 125mm×2 | 180mm×2 | 300mm×2 | 320mm×2 | 360mm×2 | 280mm×4 | 320mm×4 |

| Cylinder stroke | 3000mm | 4000mm | 5000mm | 5000mm | 6000mm | 8000mm | 10000mm |

| Cylinder thrust | 30T×2 | 30T×2 | 175T×2 | 200T×2 | 250T×2 | 150T×4 | 200T×4 |

| Motor power | 18.5kW | 22.5kW | 37.5kW | 48kW | 56kW | 68kW | 80kW |

| IF power supply needed | 160kW | 250kW | 400kW | 500kW | 600kW | 800kW | 1000kW |

The hot forming machine is only applicable for making carbon steel pipe elbows and part of the alloy steel elbows. If you are looking for machines for making stainless steel elbows, please choose our elbow cold forming machine.

As the power supply system in each country or region may be different, we can design and manufacture products according to client-side demands on the power supply voltage, frequency, etc.

Technical supports

Upon request, we can send engineers to offer on-site equipment testing and commissioning as well as installation services. Operator training service is also available. We will help clients solve all issues occurred during equipment operation.

Through our efforts, our elbow hot forming machine has been exported to Egypt, Argentina and Malaysia.