DCS50PD Weigh Filler

The DCS50PD weigh filler consists of feeding chamber, conveyor belt, digital scale, bag clamp, pneumatic control system and main control cabinet.

Advantage

1. Conveyor belt of this semi-automatic packaging system is driven by electric motor, and the weighing process is controlled by electric motor via variable frequency, ensuring speed and stability.

2. Feeding process is divided into large amount stage and small amount stage. The first stage is initiated when the gate opens fully and conveyor belt transports materials. When the amount of material in the tank reaches preset value, electric motor changes frequency and feeding speed is slowed down, which is the beginning of small amount stage.

Then by the time that the amount of material in the tank reaches preset value, the belt stops and the feeding gate closes. The whole weighing process is done.

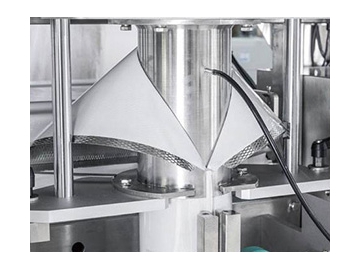

3. Digital scale on this weigh filler is fitted with three weighing cells, minimizing unbalanced loading. Moreover, weighing hopper is round-shaped and gates open inward. Flexible connection is maintained among the weighing hopper, feeding device and bag clamp, providing remarkable resistance to dust.

Furthermore, cylinder of this filling and packaging machine is absolutely separated from feeding materials for long lifespan.

4. Bag clamp of our weigh filler is equipped with double cylinders and dust discharge outlet, whereby dust generated during production process is removed in a fast and easy manner.

Application

This weigh filling system has been extensively applied to granules, flakes, powders or mixed types, such as aquatic feed, livestock feed and chemical materials, etc.

| Filling range | 20 to 50kg |

| Production rate | 420 to 600 bags/h |

| Filling accuracy | 0.1% (FS) |

| Main motor power | 2kW |

| Working condition | -20℃ to 40℃, relative humidity ≤ 90% |

| Power supply | 380±10%, 220±10% 50Hz |

| Air supply pressure | 0.4 to 0.6MPa |