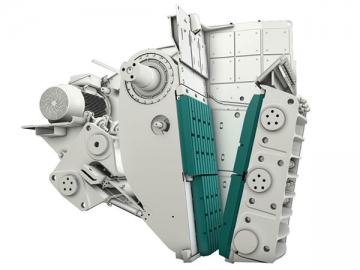

Cone Crusher

Cone crushers are commonly used in mining, metallurgy, building and road construction, and chemical industries. Our crushing machines are designed to crush medium to hard minerals, rocks, iron ore, limestone, copper ore, quartz, granite, and sandstone.

Features

1. This mineral processing plant features a large breaking force, high efficiency and capacity, low operating cost and long service life. It is convenient and inexpensive to operate.

2. The crushed materials are of equal size, reducing the circulating load.

3. Large and medium-sized crushers adopt hydraulic chamber-cleaning systems, reducing down time.

4. Cone crushers with different-sized chambers are available to meet your specific needs.

5. A greased seal effectively prevents the water feeding and drainage systems from being blocked or from the oil and water mixing.

6. An overload protection device and spring safety device allows unwanted debris and iron pieces to pass through the crushing chamber without jeopardizing the machine.

Working Principle

1. The cone crusher's motor rotates the eccentric sleeve, which drives the transmission shaft and cone to swing from wall to wall, crushing rock and ore in the process.

2. When material that cannot be crushed passes through the crushing chamber, the spring safety system enlarges the dispensing opening. After the material passes through, the dispensing opening automatically resets and the rock crusher resumes normal operation.

3. The surface of the crushing chamber is coated with a wear-resistance manganese steel lining. The size of the dispensing opening can be adjusted hydraulically or manually.

| Type | Diameter of cone | Max. feeding size | Width of discharging hole | Crushing capacity | Motor power ( kw ) | Swing frequency of main shaft | Weight (t) | Dimension (L× W× H) | |

| PYB | 900 | 900 | 115 | 15-50 | 50-90 | 55 | 333 | 11.2 | 2692 ×1640 ×2350 |

| PYZ | 60 | 5-20 | 20-65 | 11.2 | 2692 ×1640 ×2350 | ||||

| PYD | 50 | 3-13 | 15-50 | 11.3 | 2692 ×1640 ×2350 | ||||

| PYB | 1200 | 1200 | 145 | 20-50 | 110-168 | 110 | 300 | 24.7 | 2790 ×1878 ×2844 |

| PYZ | 100 | 8-25 | 42-135 | 25 | 2790 ×1878 ×2844 | ||||

| PYD | 50 | 3-15 | 18-105 | 25.3 | 2790 ×1878 ×2844 | ||||

| PYB | 1750 | 1750 | 215 | 25-50 | 280-480 | 160 | 245 | 50.3 | 3910 ×2894 ×3809 |

| PYZ | 185 | 10-30 | 115-320 | 50.3 | 3910 ×2894 ×3809 | ||||

| PYD | 85 | 5-13 | 75-230 | 50.2 | 3910 ×2894 ×3809 | ||||

| PYB | 2200 | 2200 | 300 | 30-60 | 59-1000 | 280-260 | 220 | 80 | 4622 ×3302 ×4470 |

| PYZ | 230 | 10-30 | 200-580 | 80 | 4622 ×3302 ×4470 | ||||

| PYD | 100 | 5-15 | 120-340 | 81.4 | 4622 ×3302 ×4470 | ||||

Note: These specifications are just for reference. Any changes are subject to the product.