Double Piston Continuous Melt Filter for Plastic Recycling Industry

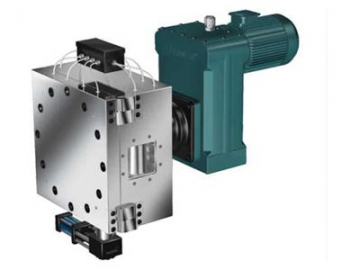

The double piston continuous melt filter features a highly cost-effective and boosted throughput rate of plastic recycling materials. In the past, people relied on screen changers or even conventional mesh filters to remove the contaminants from extruders. Nowadays, using our new generation melt filter means that you no longer need to replace the filter screen. The filter units help boost extruder output and help maintain a more consistent pressure. As a result, labor and filter replacement costs are reduced.The duplex blade melt filtration system filter is suitable for handling materials with impurities, such as paper, wood, aluminum foil, tagboard, rice husk and other not easily minced materials. The continuous cleaning melt filter is applicable to the installation of different equipment for different usages, such as granulation, aluminum plastic plate, XPS extruded sheet, film faced plywood and so on.

Parameters| Items | Mesh Diameter | Mesh Size | Suitable Extruder | Suitable Plastic | Output Per Hour | Motor Power |

| LN300 | 300X300mm | 5, 10, 15, 20, 30, 40, 50, 60, 70 | Φ120-Φ160 | PP, PE, PS, PC, ABS, PET, PA | 360kg -400kg | 2.2kw |

| LN370 | 370X370mm | 5, 10, 15, 20, 30, 40, 50, 60, 70 | Φ170-Φ180 | PP, PE, PS, PC, ABS, PET, PA | 560kg -800kg | 2.2kw |

| LN450 | 370X500mm | 5, 10, 15, 20, 30, 40, 50, 60, 70 | Φ190-Φ200 | PP, PE, PS, PC, ABS, PET, PA | 800kg -1040kg | 3.0kw |

| LN300 | 300X300mm | 5, 10, 15, 20, 30, 40, 50, 60, 70 | Φ120-Φ160 | PP, PE, PS, PC, ABS, PET, PA | 360kg -400kg | 2.2kw |

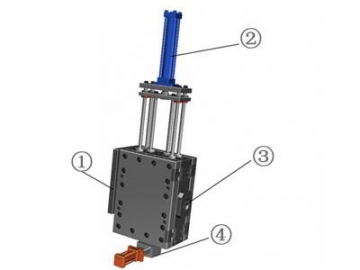

- ①Feeding inlet

- ②driving cylinder

- ③venting outlet

- ④automatic waste discharge device

The raw materials enter from the above inlet, after the push and pull through the blade, then the waste residue is discharged.

Suitable PlasticThe plastic granular extruder continuous melt filter is suitable for various types of plastics, such as PP, PE, soft PVC, PS, ABS, PA, etc. The die head of the melt filter can be replaced according to the practical situation, including:

- actual plastic customers need to filter;

- required output per hour;

- mesh size.

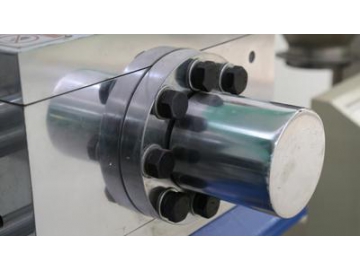

- Blade: Straight blade. The above blade near the inlet has a certain angle while the below blade is planar making it easier to extrude the scrap plastic. German quality H13, welded by hard alloy, 90° HRC, high wear-resistance.

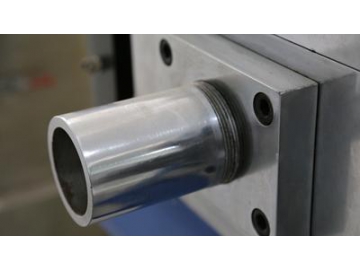

- Filter body: die steel P20, high strength, high temperature resistance, not easily deformed and broken, simple to repair and maintain.

- Mesh screen: tool steel through heat treatment to achieve 65° HRC, longer working life.

- Electric control cabinet: standard equipped with the electric cabinet from Chint Group, featuring high stability. Other brand can also be appointed by customers.

- Hydraulic power unit: four brands are available, including Taiwan Electronic Component, Nojima, Beijing Huaze and Shanghai Lixin.

- The rotating filter screen increases the filtration area. The waste residue is easy to press from the middle of duplex blades to the waste valve. Over 90% can be discharged.

- Automatic waste discharge or manual can be decided by the customers’ own needs.

- Plane extrusion doesn’t affect the performance of finished plastic granules, which are clean and superior in quality.

- The openable cover board of the filter makes it easier and more convenient to clean the inner plastic residues and surface of the screen and check the congestion or wear conditions of screen and blades.

- During filtration, problems that common for melt filters with mesh are avoided, such as screen congestion, too high pressure in head or any other issues influence the extrusion and quality.