Roll Forming Machine (for Glazed Tile)

Metal Roof Glazed Tile Roll Forming Machine

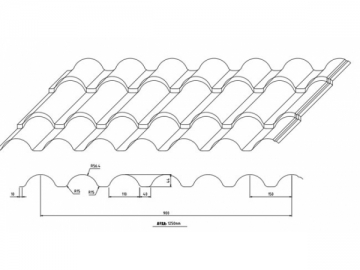

1. The colored steel metal tiles produced by the metal roof glazed tile roll forming machine look beautiful, elegant and noble. They are widely used as the roof tiles in gardens, factories, hotels, exhibition centers and villas.

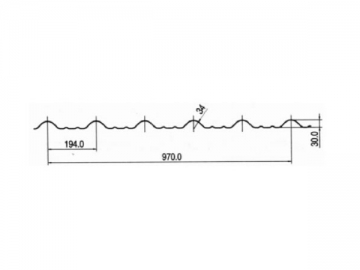

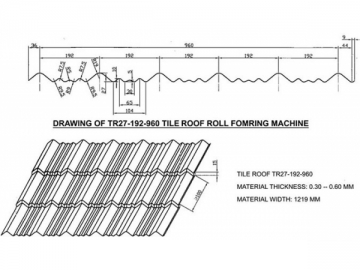

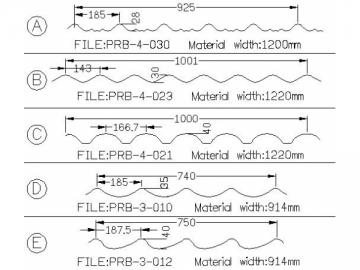

2. Coil width: 914- 1250mm, or customized according to customer requirements.

3. Coil thickness: 0.3-0.6mm

4. Decoiler: 5 Ton Manual decoiler or Hydraulic decoiler

5. The speed of the entire roll forming line is 0-5m/min ( including pressing and cutting time )

6. Working speed is 0-5m/min.

7. Forming Stations: about 13-20 steps

8. Diameter of Axis: ¢ 76mm

9. Dimension of Main Forming Machine: about 11,000mm x 1500mm x 1400mm (Lx W x H)

10. Weight of Machine: about 6.8 Ton (according to design )

11. This tile roll forming machine is suitable for coiled metal material, making the required shape after processing through uncoiling, forming continuously, pressing and cutting to length. The roll forming machine uses a PLC controlling system, AC frequency and adjusting-speed technology, in order to achieve continuous production.

| Decoiler / Uncoiler | 1 Unit |

| Feeding Guide | 1 Unit |

| Main Roof Tile Roll Forming Machine | 1 Unit |

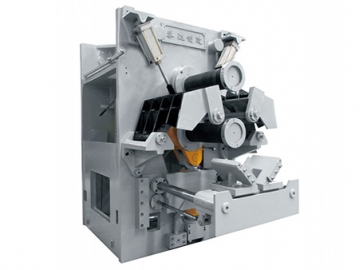

| Hydraulic Pressing for Step | 1 Unit |

| Hydraulic Cutting System | 1 Unit |

| Hydraulic Station | 1 Unit |

| PLC Computer Control Box | 1 Unit |

| Support Tables | 2 Units |

Characteristic of Roof Tile Roll Forming Machine

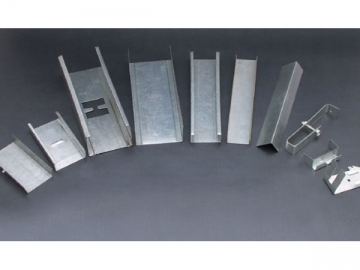

Different steel roof tile roll forming machines can produce different shapes of steel tile roof sheets in various thickness and colors. Steel tile roof sheets are the new substitutes for traditional clay or concrete tiles. They are popular due to their low cost, short building period, re-cycle use, and elegant appearance, making them widely used in villas, luxury houses, theatres, exhibition centers, and other areas.

1.This roof tile roll forming machine is used to roll form metal roof tiles. After the tiles have been roll formed by this glazed roof tile roll forming machine, the surface of each metal roof glazed tile is smooth with no scratches on the surface.

2. The steel glazed roof tile roll forming machine is equipped with a fully automatic control system with PLC control.

3. Length and quantity of sheets is adjustable.

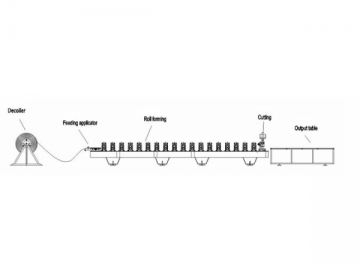

4. Roll forming process: Decoiling à Roll forming à Pressing à Cut to length.

5. Easy operation: Key in the length and quantity on the control panel.

6. 1 Year warranty, lifelong time service.

7. We also can create a custom roll forming machine, and design machines according to your specifications and profile drawings. All our machines are customized.

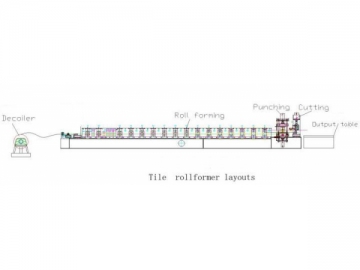

Working Process

Decoiler ---> Fedding Guide ---> Roof Tile Roll Forming ---> Pressing ---> Cut-to-length ---> Run out table

Our Advantage

1.High Quality

2.Reasonable Price

3.Excellent after Service

4.1 Year Warranty

5.More than 18 years of experience

6.Copra designing software

7.5-8 technicians to specifically carry out international installation and debugging each month.