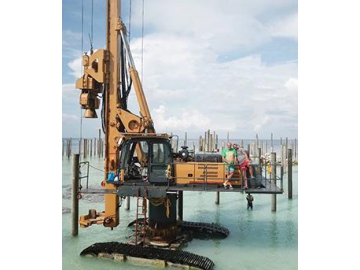

Hydraulic Scaling Rig, KQ311

Request a Quote

Underground drill rig for mining and tunneling

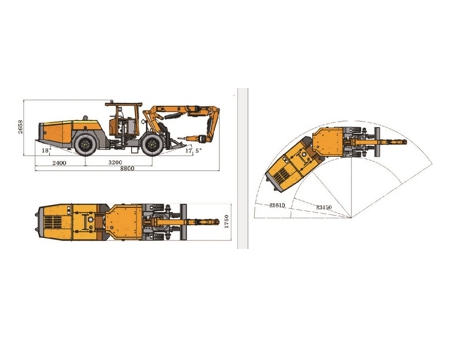

- Dimensions (L×W×H): 8800×1750×2650mm

- Weight: 12000kg

- Maximum climbing: 25%(14°)

| Dimensions | Length 8800 mm | Hydraulic hammer | Soosan SB30 |

| Width 1750 mm | Impact power | 350J | |

| Height 2650 mm | Impact frequency | 9-16Hz | |

| Weight | 12000 kg | Drive flow | 25-40L/Min |

| Engine | Cummins QSB3.9-C80-31 | Working pressure | 90-125Bar |

| power/speed | 60kW/2200rpm | Angle of swing arm | ±30° |

| Exhaust purification | Exhaust catalyzer | Pitch angle of translational arm | 45° |

| Drive system | Four-wheel drive system with wet axle | Lifting angle of mid-arm | 60° |

| Swing angle | ±6° | Pitch angle of front arm | 95° |

| Tires | 11.00-20 | Pitch angle of hydraulic hammer | 120° |

| Steering mechanism | ±40° | Angle of swing cylinder | ±90° |

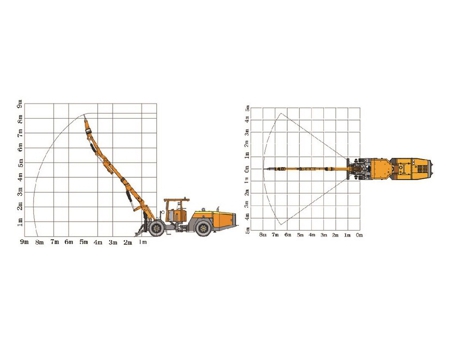

| Turning radius(inner/outer) | 3510/5610mm | Drill arm expansion and contraction | 1200mm |

| Travelling braking | Wet brake | Maximum working height | 8300mm |

| tramming speed | 10km/h | Maximum working width | 8800mm |

| Maximum gradeability | 25%(14°) | BackWard angle of cab | 15° |

| wheelbase | 3200mm | Power of water pump | 0.5kW |

| Wheel tread | 1400mm | Flow of water pump | 2L/Min |

| Ground clearance | 300mm | Cab lift | 400mm |

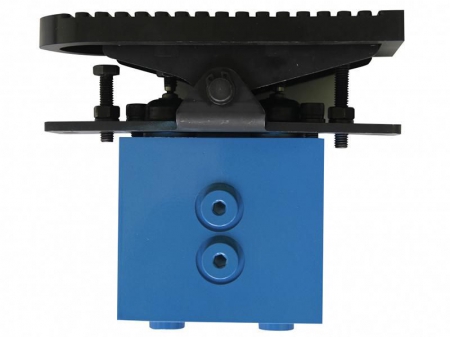

- The hydraulic scaling rig is equipped with SOOSAN hydraulic breaker, which utilizes optimized design to increase the piston and cylinder stroke, and enables the same diameter of piston and drill rod so that the hydraulic breaker and the scaling rig have the best possible compatibility therefore achieving high power output, excellent energy efficiency, less failure, easy maintenance and low operation cost;

- The telescopic boom is designed with mechanical parallel holding system to improve the coverage area and achieve drilling operations on top, side, bottom and front;

- Two electronic control handles are placed on both side of the rotating seat, giving operator great convenience for control; The electro hydraulic proportional control makes the motion of the hydraulic scaling rig more precise;

- The load sensing hydraulic system is included in this hydraulic scaling rig, ensuring energy saving, smooth running and precise positioning; Rational design of hydraulic circuit results in faster reaction and higher work efficiency; All hydraulic components are from world's renowned brands;

- The walking mechanism is constructed with mining articulated chassis, wet axle and rubber wheels, featuring high walking speed, small turning radius and powerful gradeability, enabling the hydraulic scaling rig suitable for construction site requiring frequent transports;

- Optional roof bolting mechanism replaces manual determination of roof stability, allowing personnel to avoid entering dangerous areas.

- KQ311 hydraulic scaling rig is equipped with a front push shovel for clearing ground rubble (especially around the blast piles), protecting the tires and expanding the working area to maximize the effectiveness of the platform crane. The rig is also equipped with a high-pressure water mist dust removal system to improve the working environment.

- The hydraulic scaling rig is equipped with a low-pollution level National III emission Cummins diesel engine. When matched with a four-wheel drive closed hydraulic walking system, achieves stepless speed change, strong climbing ability, and high travel speed. The exhaust purification device greatly improves underground working conditions.

- The walking brake adopts a dual-circuit multi-disc wet brake, and is equipped with a multi-disc parking brake system, providing double guarantee for braking of the scaling rig. Additionally, multiple emergency stop switches greatly enhance the safety of underground operations.

- Spacious working space, an integrated cab with lifting and pitching functions, and installation of protective devices and a series of automatic functions help drivers focus on drilling safely, quickly, and accurately. Optional wireless remote control and wired control function enhances the operational safety and equipment operability.

- The optimal layout of the scaling rig ensures good visibility for the driver, and all maintenance parts are well protected while remaining easily accessible for maintenance.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos