Inconel 718 Nickel Alloy

- N07718

- 2.4668

The Inconel 718 nickel alloy, with outstanding fabricability, excellent weldability and long term structure stability, can be made into complex parts used for various industries. The nickel-chromium alloy has superb stress-corrosion cracking and pitting resistance at both high and low temperatures, and prominent resistance to high temperature oxidation.

The usability and economy with which Inconel alloy 718 can be fabricated, combined with great tensile, fatigue, creep and rupture strength as well as perfect resistance to radiation, oxidation and corrosion, has led to its use in a wide range of applications. Good case in point is components for aircraft turbine engines or other parts in oil, chemical and nuclear power industry.

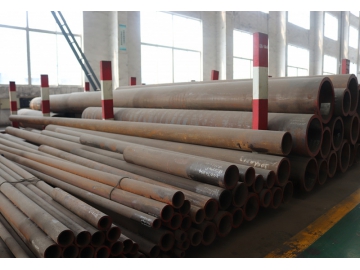

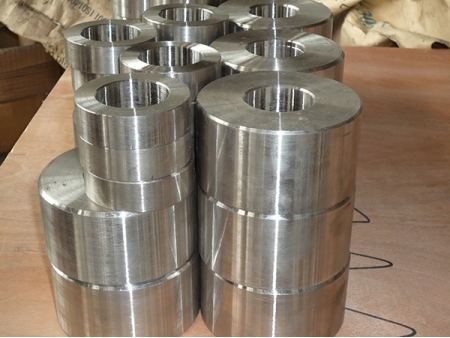

Stock and Supply of Various Inconel 718 Nickel Alloy

Common forms include tube, wire, bar, plate, etc.

-

Nickel Alloy Bar

Nickel Alloy Wire

Nickel Alloy Coil

| Ni 50.00%- 55.00% | Cr 17.00%- 21.00% | Fe Bal. | Mo 2.80%- 3.30% | Nb 4.75%- 5.50% | C 0.08% Max. | Mn 0.35% Max. |

| Si 0.35% Max. | S 0.015% Max. | Cu 0.30% Max. | Al 0.20%- 0.80% | Ti 0.65%- 1.15% | B 0.006% Max. |

every aspect of materials testing, so our customers can achieve

consistent and accurate results, every time.

Providing High Nickel Alloys and High Performance Alloys