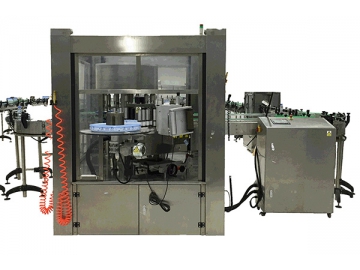

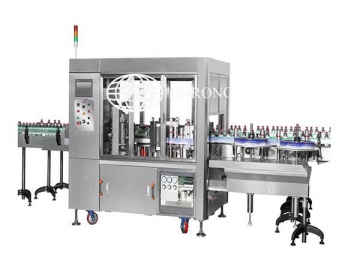

High Speed OPP Hot Melt Labeling Machine

Request a Quote

With stable running and high speed, this OPP labeling machine is more suitable for high capacity liquid packing line, which is used for filling round bottles.

Suitable for Labeling

Features

- This hot melt labeling machine can automatically attach different kinds of labels on the bottles. It is applicable to different materials of container and label. It can meet the requirements of those users who have diverse kinds of the containers. The labeling machine is the most cost-effective model to perform mass production.

- The equipment has an optimized design to make it easy and simple for users to change the bottles. In addition, it's easy to replace star wheel and guide plate or switch between manual speed adjustment and automatic speed control.

- The container is located by the upper and lower pressure plates, which can be accurately positioned in various locations.

- It is simple and quick to change configurations according to different containers and labels.

- There are two label stations available for usage and storage respectively.

- The equipment operation panel adopts LCD touch screen with man-machine interaction, which can display all kinds of operation parameters at any time, such as speed, production capacity and glue temperature.

- It adopts an automatic spiral conveyor which has large operation space.

- Centralized lubrication system allows the operation of machinery lubrication more simple to ensure long service life. The machine is simple and convenient to maintenance.

- The hot melt labeling machine uses rear-mounted cam design to simply replace the bottle-type.

- Overload protection provides high security during machine operation. Multi-point and fault protection device ensures the sound-light alarm to maximize machine operators' safety.

- Adopting double shaft propeller allows for feeding bottles smoothly in a high-speed manner.

- Automatic film tension control & detection device, and feedback control system ensure high quality labeling on bottles.

Specifications

| Voltage | 380V, three-phase, 50HZ |

| Total power | 8kW |

| Conveyor speed | 30m/min (conveyor speed can be adjusted according to actual production conditions) |

| Speed adjustment method | stepless speed control |

| Maximum labeling speed | 150m/min |

| Production capacity | 2000-1200 labels/hour (production speed can be adjusted according to actual conditions) |

| Labeling accuracy | ±1mm |

| Maximum label width (height) | 150mm (standard width, the width can be increased according to the actual product requirement) |

| Maximum label length | 500mm |

| Maximum outer diameter of label | 600 mm |

| Paper core diameter | 152mm |

| Labeling glue | hot melt glue, only apply glue on both ends of the label |

| Gluing temperature | 120~160℃ |

| Label material type | OPP film, paper-plastic composite film, paper |

| Labeling station | 3 |

| Number of labeling molds | 1 set of standard configuration (to meet the specifications of the product provided, each set of molds includes bottle feed screw, bottle feed star wheel, bottle outlet star wheel, bottle holder, etc.) |

| Compressor specifications | 0.6m3/min (provided by the user) |

| Machine length | Total length: 2615mm (the length of the labeling machine with conveyor belt: 2615mm; can be adjusted according to the actual size of the customer's production line) |

| Machine width | 1800mm |

| Mechanical weight | 2000kg |

Machine Details

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos