Double PE Coated Paper Cup Forming Machine MG-X12

Paper cup making machinery, disposable coffee cup making machine, CE certificate paper cup machine, paper cup machine, paper cup making machine prices,paper bowl machine

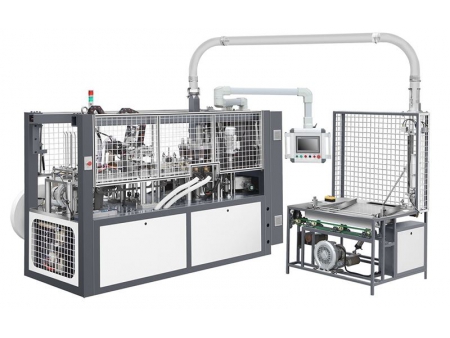

Equipped with photoelectric sensor, micro frequency converter, precise cup counter and other processing devices, this multi-station automatic cup former independently finishes a series of cup manufacturing steps, like feeding, sealing, bottom cutting, etc. According to the market survey, it has often been chosen as the ideal choice for making the drink cup, especially for single/double PE coated cups. Characterized by easy operation, stable properties, small size and high economic benefits, this paper converting instrument has attracted more and more attention from investors.

This kind of cup maker will offer you comfortable drinking. It is suitable for coffee, beverage, tea, ice cream and hot drinks cops with high performance.

Attractive Features

1. The ultrasonic aluminum welding head provides 10,000 times of vibration every second when sealing the cup, suitable for making both single and double PE coated cups.

2. Featured by high precision and anti-abrasion, the knurling device makes good use of imported bearings. The pressure provided by this device is at least 10 times higher than that by traditional knurling equipment, leading to clear and nice pattern.

3. The sealing heater ensures good sealing effect while saves electricity and manpower.

4. By using a retractable knife, even wrinkles at the bottom and low leakage are achieved. Additionally, when changing molds, there is no need to move the whole punching holder, which does no harm to the machine and saves replacing time.

Main Parts of Cup Making Machine

-

The machine enclosure is easy to disassemble, thus simplifying the daily cleanliness and maintenance.

The machine enclosure is easy to disassemble, thus simplifying the daily cleanliness and maintenance. -

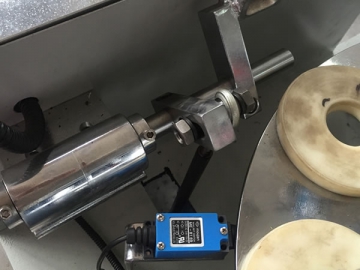

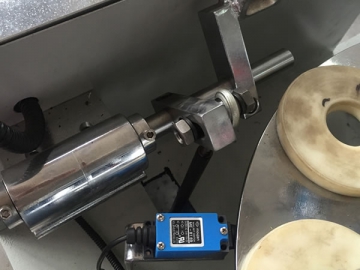

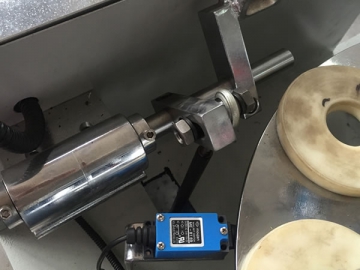

It is this stretchable knife that provides good sealing between cup bottom and wall and decreases water leakage rate.

It is this stretchable knife that provides good sealing between cup bottom and wall and decreases water leakage rate. -

This bottom rolling device provides 5 times embossing force of traditional rolling machine. It guarantees clear and uniform pattern and low leakage.

This bottom rolling device provides 5 times embossing force of traditional rolling machine. It guarantees clear and uniform pattern and low leakage.

-

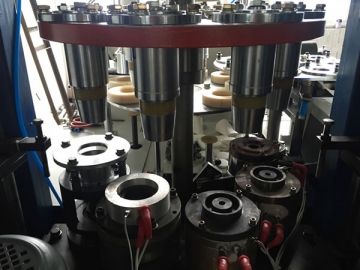

In order for good condition and high quality, all molds are manufactured by CNC lathes.

In order for good condition and high quality, all molds are manufactured by CNC lathes. -

Outfitted with multi-position detection, this alarm system shuts down the paper cup making machinery as long as it finds cup bottom shortage or bottom accumulation.

Outfitted with multi-position detection, this alarm system shuts down the paper cup making machinery as long as it finds cup bottom shortage or bottom accumulation. -

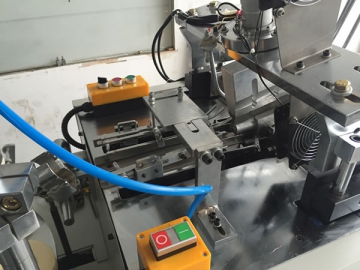

Ultrasonic is used to do sealing for fastness and high strength. It's capable to make single and double PE coated cups.

Ultrasonic is used to do sealing for fastness and high strength. It's capable to make single and double PE coated cups.

-

A robot arm is applied for cup overturn. It's safe and secure.

A robot arm is applied for cup overturn. It's safe and secure. -

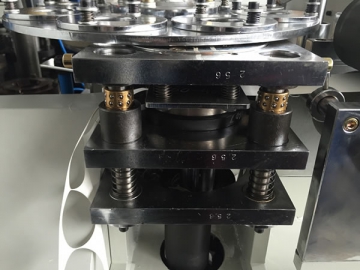

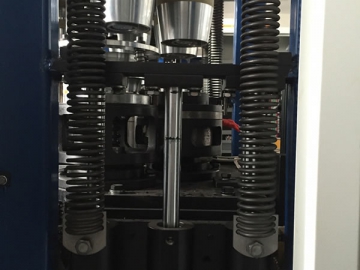

Three high strength shafts and two huge springs lead to stable machine running.

Three high strength shafts and two huge springs lead to stable machine running.

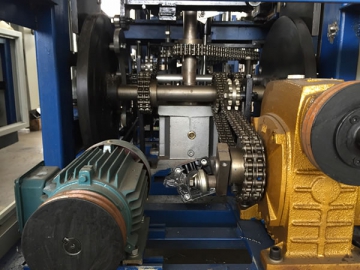

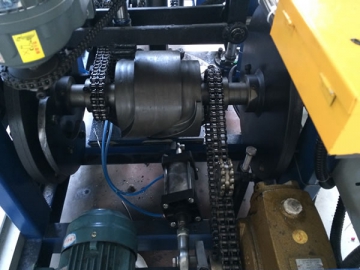

Currently, there are two transferring systems developed for clients to choose:

-

Traditional gearbox and chain type is relatively economical.

Traditional gearbox and chain type is relatively economical. -

The modern cam and chain transmission type is more durable and runs stably. It has become hot in recent years.

The modern cam and chain transmission type is more durable and runs stably. It has become hot in recent years.

| Model | MG-X12 |

| Production capacity | 50pcs/min |

| Cup capacity | 2-12 OZ (50ml-350ml) |

| Raw material | 150-350g Single coated paper/ Double PE coated paper |

| Power source | 220V 50Hz 1 phase / 380V 50Hz 3 phase |

| Power | 3.5KW |

| Net weight | 1500KG |

| Dimensions | 2800mm×1400mm×1700mm |

| Air consumption | pressure: 0.4 Mpa; Input: 0.6m3/minute |

| Production time | According to paper size, paper material and PE coating |

| Video link | https://www.youtube.com/watch?v=pJl1HUUJQFw |

Note

1. We are able to provide customized service, including specifications, paper cup molds and so on.

2. You need to buy an air compressor for manufacture of double PE coated paper cups.

Maintenance

Maintenance of MG-X12 doubel PE paper cup forming machine should be carried out in strict compliance with the maintenance guidance.

1. Every component should be cleaned up carefully.

2. For sanitation and cleanliness, a fixed schedule should be maintained to clean and wipe the machine. Greasy dirt should be removed from the paper, die and roller. The machine must be kept from paper scraps, dust, plastic rolling, etc.

3. Glycerol can be used to lubricate the entire machine.

Package

All machines are packaged by wooden case.

After-sale Service

1. A user guide is included to assist with the machine installation and adjustment and help solve problems that may be encountered.

2. The MG-X12 doubel PE paper cup forming machine will be adjusted one week prior to delivery to make sure it is in perfect condition.

3. Technicians are available to guide the installation and adjustment on site. This service would be at the buyer's expense, which includes the technician's salary ($100 USD/day), traveling expense, accommodation, consulting fee, etc.

4. Free training is available and ongoing until the operator fully understands the operation and maintenance of our machine. The buyer should cover traveling and accommodation expenses of our technicians.

5. Our company provides wearing parts at no charge for one year.

Warranty

1. We offer a one-year warranty for the MG-X12 Automatic High Speed Paper Cup Forming Machine from the shipment date.

2. The warranty does not cover normally worn components.

3. We will not be responsible for any damage caused by misuse, improper handling, negligent maintenance, intentional injury or other damages.

Ruian Mingguo Machinery Co., Ltd.

Tel.:

Fax: 86-577-65012527