Steel Cord Conveyor Belt

The steel cord conveyor belt can be used to a wide range of applications such as coal, mining, port, metallurgy, electricity, chemical industry and so on.

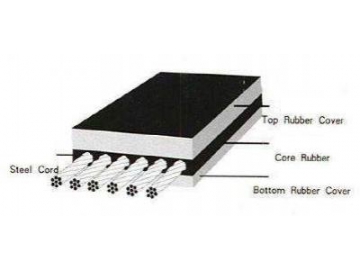

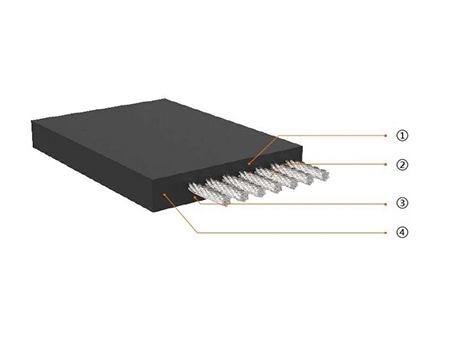

The carcass consists of the evenly arranged, left and right twisted galvanized steel cords and the core rubber with high adhesion properties. The top and bottom rubber are covered on the carcass to form the conveyor belt.

- ST series

- GX series

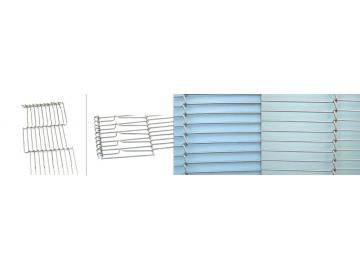

- Steel cord structure

- High tensile strength. Long service life. Low elongation allows short take-up strokes. Good troughability. Ideal for long-distance, large-capacity and high-speed transportation of materials.

- The core rubber can fully permeate into the cords to achieve high adhesion properties between the rubber and steel cords.

- Good rust resistance of steel cord.

- Mutual shearing and twisting of steel cords are relived and resistant to dynamic fatigue to extend the service life of the steel cord conveyor belt.

Structure: on the side or sides perpendicular to the steel cord, transversely arrange steel cords, steel wire cord, fiber cord, fiber fabric or other reinforcement layer.

Features: good shock resistance and tear resistance.

| Item | ST 630 | ST 800 | ST 1000 | ST 1250 | ST 1600 | ST 2000 | ST 2500 | ST 3150 | ST 3500 | ST 4000 | ST 4500 | ST 5000 | ST 5400 |

| Longitudinal tensile strength (N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

| Max. steel cord nominal diameter (mm) | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 |

| Steel cord spacing (mm) | 10 | 10 | 12 | 12 | 12 | 12 | 15 | 15 | 15 | 15 | 16 | 17 | 17 |

| Top cover thickness (mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 |

| Bottom cover thickness (mm) | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8.5 | 9 |

| * Referenced rubber belt kg/㎡ | 18.6 | 20.3 | 23.5 | 25.4 | 27.0 | 33.1 | 36.1 | 42.5 | 45.5 | 46.6 | 51 | 59 | 62 |

| Width (mm) | The number of steel cords | ||||||||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | ||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 77 | 77 | 71 | 66 | 66 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 90 | 90 | 84 | 78 | 78 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 104 | 104 | 96 | 90 | 90 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 117 | 117 | 109 | 102 | 102 | |

| 2000 | 159 | 159 | 159 | 159 | 128 | 128 | 130 | 130 | 121 | 113 | 113 | ||

| 2200 | 176 | 141 | 141 | 144 | 144 | 134 | 125 | 125 | |||||

Note: for 100-350m conveyor belt, the length of the belt needs to decide together based on the thickness, width, transportation and installation conditions.

*The weight of the rubber belt varies based on the cover rubber thickness and density.

| Model | ST 630 | ST 800 | ST 1000 | ST 1250 | ST 1600 | ST 2000 | ST 2500 | ST 3150 | ST 3500 | ST 4000 | ST 4500 | ST 5000 | ST 5400 |

| Min. roller diameter (mm) | 500 | 500 | 630 | 800 | 1000 | 1000 | 1250 | 1400 | 1600 | 1600 | 1600 | 1800 | 1800 |

| Model | ST/S 630 | ST/S 800 | ST/S 1000 | ST/S 1250 | ST/S 1600 | ST/S 2000 | ST/S 2500 | ST/S 2800 | ST/S 3150 | ST/S 3500 | ST/S 4000 | ST/S 4500 | ST/S 5000 | ST/S 5400 |

| Longitudinal tensile strength (N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

| Max. steel cord nominal diameter (mm) | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 7.5 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 |

| Top cover thickness (mm) | 5.0 | 5.0 | 6.0 | 6.0 | 6.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.5 | 9.0 |

| Bottom cover thickness (mm) | 5.0 | 5.0 | 6.0 | 6.0 | 6.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.5 | 9.0 |

| Width (mm) | The least number of steel cords | |||||||||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | 50 | ||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 64 | 59 | 55 | 55 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 76 | 77 | 77 | 71 | 66 | 66 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 89 | 90 | 90 | 84 | 78 | 78 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 101 | 104 | 104 | 96 | 90 | 90 |

| 1800 | 171 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 114 | 117 | 117 | 109 | 102 | 102 |

| 2000 | 196 | 196 | 159 | 159 | 159 | 159 | 128 | 128 | 128 | 130 | 130 | 121 | 113 | 113 |

| 2200 | 216 | 216 | 176 | 176 | 176 | 176 | 141 | 141 | 141 | 144 | 144 | 134 | 125 | 125 |

| Item | Index |

| Tensile strength | ≧15.0Mpa |

| Elongation at break | ≧350% |

| Abrasion loss | ≦200mm³ |

| Model | Adhesive strength of steel cord(≧KN/m) | Model | Adhesive strength of steel cord(≧KN/m) | ||

| Before aging | After aging | Before aging | After aging | ||

| ST/S630 | 67 | 50 | ST/S2800 | 134 | 124 |

| ST/S800 | 75 | 69 | ST/S3150 | 143 | 135 |

| ST/S1000 | 82 | 77 | ST/S3500 | 151 | 140 |

| ST/S1250 | 90 | 84 | ST/S4000 | 155 | 144 |

| ST/S1600 | 97 | 90 | ST/S4500 | 168 | 157 |

| ST/S2000 | 112 | 105 | ST/S5000 | 186 | 175 |

| ST/S2500 | 130 | 122 | ST/S5400 | 192 | 180 |

| GX 630 | GX 800 | GX 1000 | GX 1250 | GX 1600 | GX 2000 | GX 2500 | GX 3000 | GX 3500 | GX 4000 | GX 4500 | GX 5000 | GX 5500 | |

| 6+7+6 | 6+7+6 | 6+7+6 | 6+7+6 | 7+9+7 | 7+9+7 | 8+11+8 | 8+12+8 | 8+12+8 | 8+13+8 | 8+14+8 | 8+14+8 | 8+15+8 | |

| Longitudinal tensile strength (N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 | 5500 |

| Max. steel cord nominal diameter (mm) | 4.5 | 4.5 | 4.5 | 4.5 | 6.0 | 8.0 | 7.2 | 8.3 | 8.7 | 9.1 | 9.7 | 10.9 | 11.3 |

| Steel cord spacing (mm) | 20 | 17 | 13.5 | 11 | 20 | 16 | 17 | 18 | 18 | 17 | 16 | 17 | 17 |

| Rubber belt thickness (mm) | 19 | 19 | 19 | 19 | 23 | 23 | 27 | 28 | 28 | 29 | 30 | 30 | 32 |

| *Referenced rubber belt kg/m2 | 21.3 | 23.9 | 25 | 25.7 | 32.2 | 33.7 | 40.2 | 41.9 | 43.6 | 46.6 | 49.8 | 51.8 | 55.9 |

| Width (mm) | The number of steel cords | ||||||||||||

| 800 | 38 | 45 | 56 | 69 | 38 | 47 | 44 | 43 | |||||

| 1000 | 48 | 56 | 70 | 87 | 48 | 60 | 56 | 53 | 53 | 56 | 60 | 56 | 56 |

| 1200 | 68 | 86 | 104 | 58 | 72 | 68 | 64 | 64 | 68 | 72 | 68 | 68 | |

| 1400 | 100 | 122 | 66 | 84 | 78 | 74 | 74 | 79 | 84 | 79 | 79 | ||

| 1600 | 116 | 140 | 76 | 95 | 90 | 86 | 85 | 90 | 96 | 91 | 91 | ||

| 1800 | 127 | 157 | 86 | 108 | 102 | 96 | 96 | 101 | 107 | 103 | 103 | ||

| 2000 | 142 | 173 | 96 | 120 | 113 | 107 | 107 | 113 | 120 | 114 | 114 | ||

| 2200 | 132 | 125 | 118 | 118 | 125 | 133 | 125 | 125 | |||||

* Weight of 1m long and 1m wide belt. The weight of the rubber belt varies based on the cover rubber thickness and density.

| Model | GX630 | GX800 | GX1000 | GX1250 | GX1600 | GX2000 | GX2500 | GX3000 | GX3500 | GX4000 | GX5000 | GX5500 |

| Min. roller diameter (mm) | 800 | 800 | 800 | 800 | 1000 | 1000 | 1250 | 1400 | 1600 | 1800 | 1800 | 2000 |

According to the characteristics of the cover rubber, the following types of rubber covers are available: ordinary type, flame-retardant, cold resistant, abrasion resistant, heat resistant, heat resistant, acid resistant, oil resistant, high-grade type and etc.

| Type | Main parameters |

| Ordinary type | GB/T9770 |

| High grade type | DTN22131 Grade X |

| Flame-retardant type | MT147 MT6 68 |

| General flame-retardant type | GB/T10822 |

| Heat resistant type | GB/T20021 |

| Abrasion resistant type | Abrasion loss≦90mm3 |

| Heat and abrasion resistant type | ≦125℃, abrasion loss≦150mm3 |

| Cold resistant type | Brittle temperature: -20℃-50℃ |