Hydraulic Die Spotting Press (Impact Simulation Type), ST Series

This advanced hydraulic die spotting press utilizes the tremendous impact force generated during the moment of contact in freefall, replacing the conventional static pressure used in die presses for inspection purposes, resulting in superior die spotting quality compared to traditional die spotting presses of the same mold surface size.

The hydraulic die spotting press is engineered with meticulous attention to detail. High standards of configuration and computer-aided design ensure exceptional performance. Critical components are processed using state-of-the-art machining centers to guarantee precision, while advanced heat treatment techniques enhance the durability of important and wear-prone parts. The hydraulic system combines high-performance hydraulic components in an optimized configuration, while the control section features a dedicated die spotting press computer control system.

- Max. mold weight: 12 ton

- Max. upper mold weight: 4 ton

- Ejecting capacity: 22 ton

- Mold open capacity: 370 ton

- Max. mold weight: 16 ton

- Max. upper mold weight: 8 ton

- Ejecting capacity: 63 ton

- Mold open capacity: 950 ton

- Max. mold weight: 20 ton

- Max. upper mold weight: 10 ton

- Ejecting capacity: 63 ton

- Mold open capacity: 950 ton

- Max. mold weight: 36 ton

- Max. upper mold weight: 18 ton

- Ejecting capacity: 63 ton

- Mold open capacity: 1500 ton

- Compact design, reducing the equipment's overall size by approximately 25% compared to traditional die spotting presses of the same mold surface size. This allows for higher utilization of your factory space.

- Concealed oil tank and motor, contributing to a clean and aesthetically pleasing appearance.

- Reinforced high rigidity base, ensuring overall stability even under high impact forces.

- Practical and reliable fault detection and alarm functions, enhancing operational safety and performance.

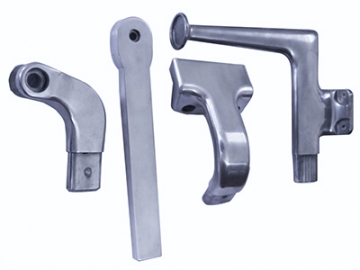

- Utilizes graphite copper sleeve guides for oil-free and self-lubricating operation, promoting a cleaner and more environmentally friendly machine. These guides offer a low and stable friction coefficient, preventing any adhesive phenomena.

- Multiple measures in mechanical, electrical, and hydraulic systems ensure consistent rotation and reset positions.

- Equipped with a lower worktable featuring high-precision positioning and lifting devices, enhancing operational precision.