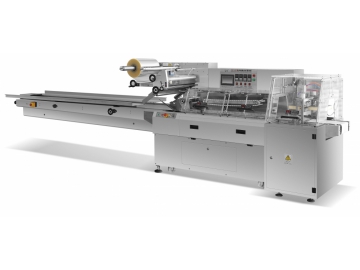

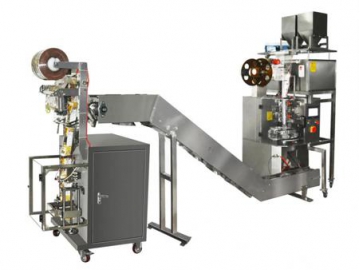

Vertical Form Fill Seal Machine , DC-890A

Request a Quote

Automatic VFFS single-lane machine for back seal stick pack packaging

- Bag width

11-45mm (non-adjustable once selected)

- Bag length

30-180mm (adjustable)

- Packing speed

30-50 bags/min

DC-890A automatic single-lane VFFS packaging machine is ideal for back seal stick packaging of liquids, powders, particles, and other products in the food, medicine, and daily chemical industries. The vertical form fill seal machine offers simple, user-friendly operation; users only need to input the values in the system to adjust sachet lengths, production time and store product parameters. It's the perfect solution for customers with high production capacity and speed, as well as those needing back seal packing.

Specifications

| Bag width | 11-45mm (non-adjustable once selected) |

| Bag length | 30-180mm (adjustable) |

| Filling volume | 1-40ml |

| Packing speed | 30-50 bags/min |

| Power supply | 220V, 50Hz, 3.5kW |

| Air consumption | 0.2L/min |

| Machine weight | 350kg |

-

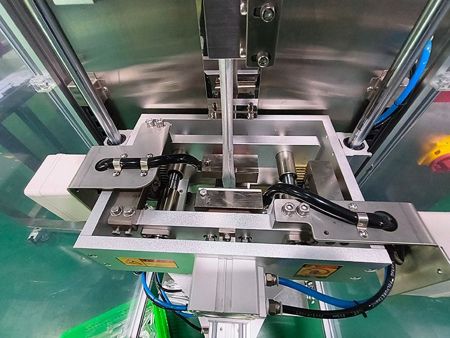

When feeding, the material is swiftly acquired, preventing any droplets from causing a leak due to clamping the bag. Additionally, the horizontal pressure from sealing is even, meaning that whether you start from the middle or both ends of the bag, the lines will be consistent and the seal will be tight.

When feeding, the material is swiftly acquired, preventing any droplets from causing a leak due to clamping the bag. Additionally, the horizontal pressure from sealing is even, meaning that whether you start from the middle or both ends of the bag, the lines will be consistent and the seal will be tight. -

Film rolling and running helps maintain the tension of the film, resulting in a flat and unwrinkled bag.

Film rolling and running helps maintain the tension of the film, resulting in a flat and unwrinkled bag. -

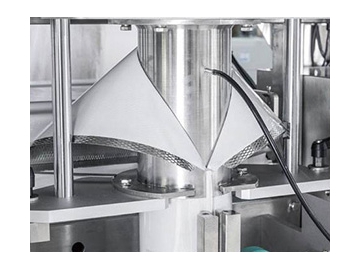

The advanced rigid balance technology plus synchronous gear structure of transverse sealing ensures an even and effortless seal with uniform pressure.

The advanced rigid balance technology plus synchronous gear structure of transverse sealing ensures an even and effortless seal with uniform pressure. -

This mold is constructed with imported mold knives, meticulously polished through 12 steps to provide a neat, continuous surface and a smooth, burs-free edge.

This mold is constructed with imported mold knives, meticulously polished through 12 steps to provide a neat, continuous surface and a smooth, burs-free edge. - This mold is constructed with imported mold knives, meticulously polished through 12 steps to provide a neat, continuous surface and a smooth, burs-free edge.

- Two cooling systems are in place, guaranteeing a smooth bag incision without any burrs and providing optimal protection for the cutter.

- Panasonic servo motor is a great feature of this sealing machine, making adjustments and corrections swift and easy. It offers convenient, speedy changes to film rolling and effectively corrects any deviations.

Standard safety door (for safety production)

Standard safety door (for safety production) Alignment tool

Alignment tool Feeding device

Feeding device Longitudinal sealing roller (heat sealing)

Longitudinal sealing roller (heat sealing) PLC operation interface and temperature control table

PLC operation interface and temperature control table Easy-tear seal cutter

Easy-tear seal cutter

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos