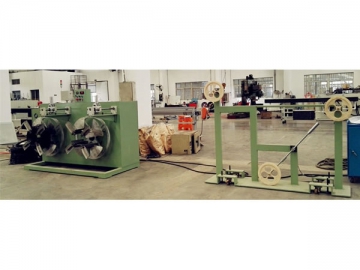

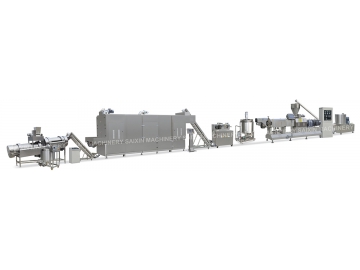

HDPE silicone core tube (micro duct) extrusion line

Silicone Core Tube Extrusion Line / Micro Duct Extrusion Line / HDPE Silicone Tube Extrusion Line

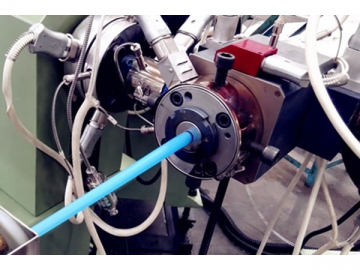

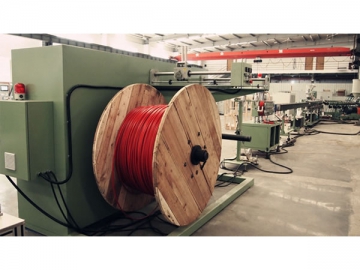

An HDPE silicone core pipe (micro duct), or silicone pipe for short, is a new composite pipe with a silica gel solid inside the pipe, and whose primary material is HDPE. This pipe is widely used in communication cable systems.

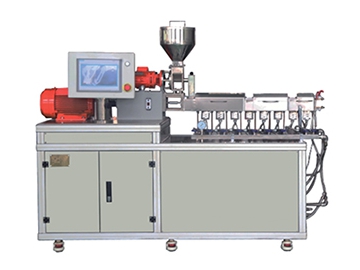

Equipment Features

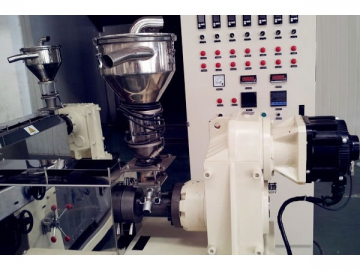

The screw on the HDPE extruder uses Taiwanese technology processing to provide an excellent plasticization and high extrusion efficiency.

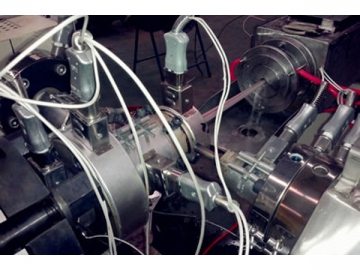

The high pressure positive displacement mold ensures the headpiece is capable of a higher melting pressure, which improves the overall pipe quality and stabilizes the extruding process.

The cooling vacuum trough is made of SUS304 stainless steel. The supporting frame equipped with a spiral lifter can achieve a 3D adjustment, allowing operation to be more convenient. The high quality liquid circulating vacuum pump provides a steady vacuum negative pressure, and the stainless steel water tank and centrifugal pump are combined with an external cooling water supply to form a water circulation system.

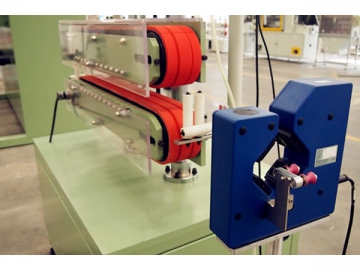

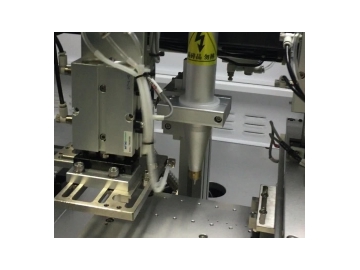

The precision tube extrusion line uses a high performance LaserMike measuring system, forming a closed-loop feedback control to eliminate diameter deviation online.

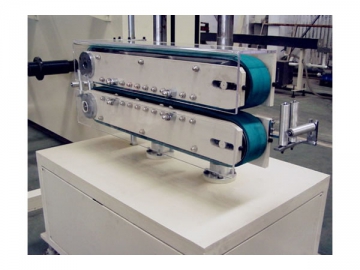

The puller uses a multi-layer wear resistant synchronous belt with no sliding phenomenon. The high level precision roller drive traction, YAKSAWA servo driving system and the ABB AC driving system achieve a stable pulling performance.

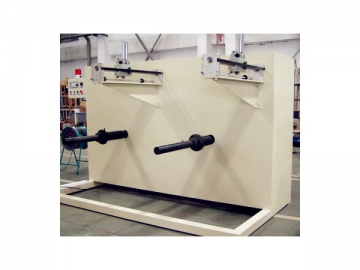

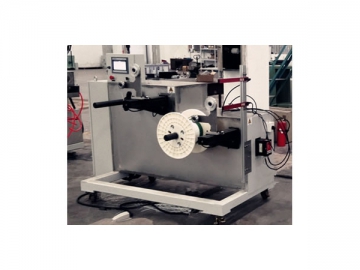

The specially designed winding machine is equipped with a tension induction regulator which applies to soft pipes. This keeps the winding under a natural relaxed state. When the tension conditions change, the fluctuation is kept under a manageable scope, in order to avoid tube overdrawing by a winding speed that is too fast or too slow.