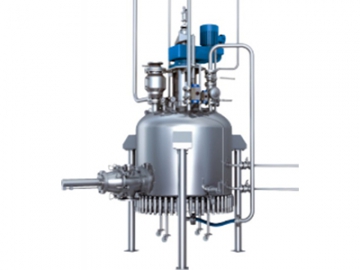

Stainless Steel Nutsche Filter Dryer (NFD)

Request a Quote

The equipment can filter, clean and dry to replace the vacuum filter, pressure filter, double conical dryers, drying oven and so on. The filtration, cleaning, drying and solid unloading can all be finished with one machine.

The dryer can realize fully-closed continuous operation in whole process. What’ more it can be used for the production of sterile required products or poisonous products, as a result of which it’s widely used in pharmaceutical, chemical, pesticide, food industry.

Functions

The equipment can make the filter cake and output finished products from the side outlet with residue less than 8mm. The product from the equipment can be directly wrapped. The whole process can be divided into three stages:

- Filtration: separate the filter cake and mother liquor. The thickness of filter cake can be up to 500mm.

- Cleaning: purify the filter cake. Move the residue of mother liquor first and carry out pre-dehydrating. Then mix the filter cake and washing buffer to suspend the material so that the filter cake can be fully cleaned.

- Drying: filter cake is dried. While the filter cake is mixed by the mixer, the sidewall, the bottom of filter plate and the baffles will heat the filter cake to evaporate the water quickly. Meanwhile, the equipment will remove the air in the tank to promote the evaporation speed and pump hot nitrogen to move the steam.

- Inner vessel design pressure: -0.1/0.35MPa

- Inner vessel design temperature: 60℃

- Jacket design pressure: 0.35MPa

- Jacket design temperature: 70℃

- Filtration area: 0.2m²-5m²

- Stirring speed: 0-15r/min

- shaft lift: 100mm-350mm

- Floor material: 304 or 316L stainless steel

- Filtration material: six layers of 316L sintered metal filters or filter cloth.

- Size pore of filter: 5um-50um (customized)

- The chassis of mixer can be removed using the hydraulic cylinder. The chassis equips with channel or pipes heating system.

- The agitating shaft which can rotate reversely is driven by motor speed reducer and the speed is adjusted by frequency converter.

- Support in line cleaning and sampling and 121℃ steam sterilization.

- The chassis and tank body are connected by U-shape seal without dead space. It meets the GMP requirements.

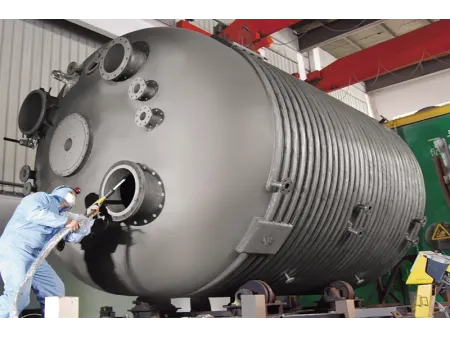

- Vessel body

- Mixing system

- Filtration system

- Side outlet system

- Heating and insultation system

- Hydraulic lift system

- Control system

| Specification(mm) | Capacity(m³) | Filter area(m²) | Mixing stroke(mm) | Motor power(kW) |

| φ1000 | 1.2 | 0.8 | 300 | 5.5 |

| φ1200 | 1.5 | 1 | 300 | 5.5 |

| φ1400 | 2.2 | 1.5 | 400 | 7.5 |

| φ1600 | 3 | 2 | 400 | 7.5 |

| φ1800 | 3.5 | 2.5 | 400 | 11 |

| φ2000 | 4 | 3 | 400 | 11 |

| φ2400 | 6 | 4.5 | 450 | 15 |

| φ2800 | 9.5 | 6 | 450 | 18.5 |

| φ3000 | 10.2 | 7 | 500 | 22 |

| φ3200 | 12 | 8 | 550 | 30 |

| φ3600 | 18 | 10 | 550 | 45 |

Related Manufacturies

Leave Message

Similar Manufacturies and Parts

Manufacturer Advertising

More

Similar Manufacturies and Parts

Videos