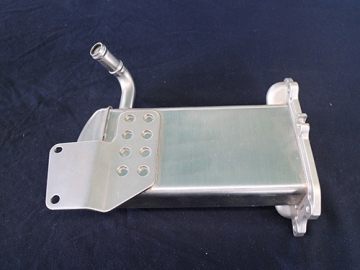

Exhaust Gas Recirculation (EGR) Cooler

Request a Quote

Engine Cooling , Vehicle Parts, Auto Parts

CAIEC SHANGHAI specializes in the production of exhaust gas recirculation (EGR) coolers, which are a key component of the EGR system and can be used for both automobile OEM and aftermarket. With expertise in core techniques for EGR cooler design and production, the company has set up an EGR cooler production line with an annual production capacity of more than 100,000 pieces. Currently the company is able to supply more than 50 popular models of EGR coolers to meet customer needs in Europe, America, and Southeast Asia.

Features

- Construction: stainless steel tubing

- Material: 304/316 stainless steel optional

- Compact structure

- The excellent cooling performance meets the design requirements to reduce exhaust gas temperatures.

- Capable of withstanding low-frequency-vibrations and strong alternate stresses caused by severe thermal shocks.

- Processed by vacuum brazing, the EGR coolers are capable of withstanding a high working pressure and harsh working environments.

- The welds are flat and smooth to ensure a better product appearance and quality.

- Better cooling performance and aesthetic appearance due to the use of high-quality stainless-steel material.

- All EGR coolers are delivered with gaskets.

- All EGR coolers are subject to the leakage testing.

Details

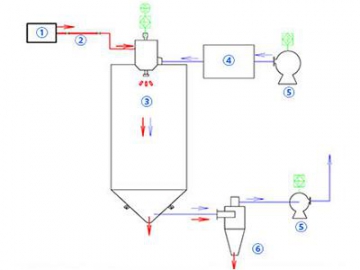

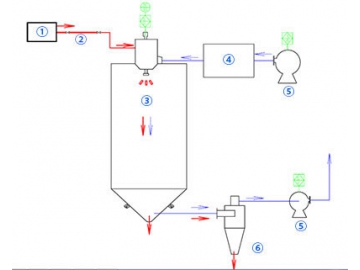

- The vacuum brazing technique makes the welding joints strong, reliable and smooth.

-

- Bright, clean and smooth surface.

-

- The corrugated pipes are bent uniformly without any defects.

-

- The brazing flux goes into the joints completely, showing perfect matching and excellent brazing.

-

- Strong and leak-tight brazed welds with excellent thermal properties can withstand extremely high temperatures associated with engine operations.

Our Advantages

- The EGR team is comprised of experts with more than 15 years of experience in the development and manufacturing of EGR products.

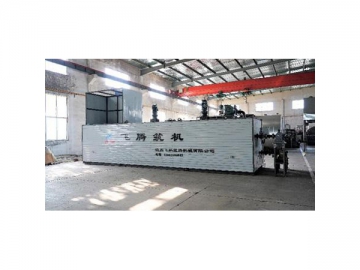

- The company produces more than 50 popular models of EGR coolers to meet varying market demands. A medium-batch production line has been set up for the production of multi-model EGR cooling products. This production line, with a production area of 3,000 square meters, has an annual production capacity of 100,000 EGR coolers.

- The EGR cooler line is equipped with more than 50 sets of manufacturing equipment and over 100 sets of high-precision tooling and molds. The equipment includes auto pressing machine, CNC controlled glue dispensing machine, high vacuum brazing furnace, precision detector, high-quality press and hydraulic machine.

- The company applies IATF16949 quality management standards to ensure the final quality of all its EGR products and components. Based on the technical characteristics of EGR cooling products, the company fully utilizes the special manufacturing techniques, the specific production parameters and the specialized team to ensure the final product quality. The first pass yield of EGR coolers is 98% - a rate much higher than its competitors.

- Over 50000 EGR coolers have been exported to Europe, America, Australia, Southeast Asia and the Middle East, winning a trusted and popular international reputation.

- CAIEC Shanghai will continue with investments to improve its production capacities. One such investment is the construction of a 9000㎡-factory with an estimated production scale of 300,000 EGR coolers and EGR system products per year within two years.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos