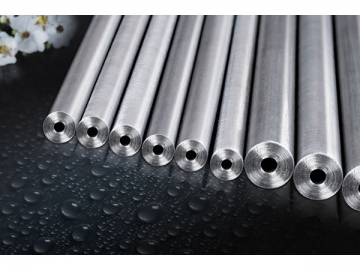

Galvanized Steel Tube

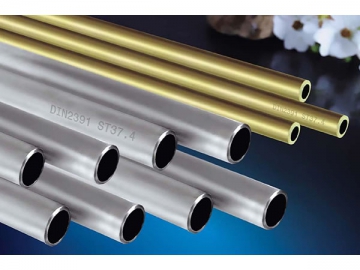

Steel Tubes / Automotive Steel Tubes / High Precision Steel Tubes

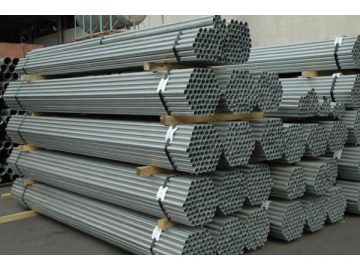

When producing galvanized steel tubes, we utilize advanced technical processing and use a chemical liquid imported from Germany. Both the inner and outer surfaces of the high precision steel tubes can be galvanized, giving them a high homogeneity and an excellent rust resistant performance.

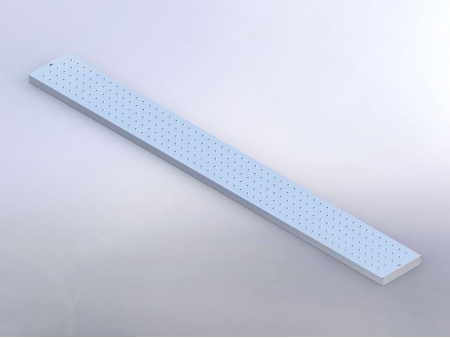

The maximum length of these automotive steel tubes is 10 meters, and the zinc color choices include white, yellow, and army green.

Dimension range: Outer diameter-3-89mm, wall thickness- 0.4-10mm

Zinc wall thickness 8-30um, and customized as per customer requirements.

Salt spray test: common requirements- 80-120 hours, high requirements- 120-300 hours

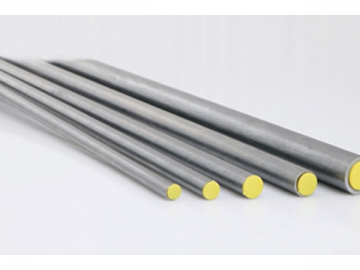

Cr 6 free, environmental type

Process Description

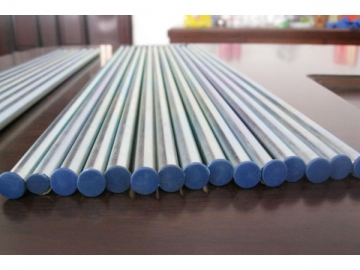

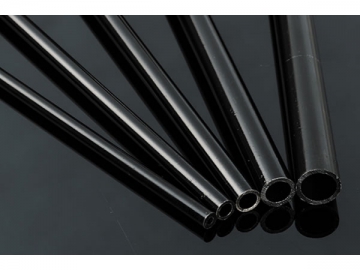

Using a high precision, fine drawn bright seamless steel tube as the steel pipe for galvanizing, the outer wall of the steel pipe Is cold-galvanized, and both ends are covered for dust protection. The pipe length can be produced to be less than 6 meters.

Zinc color: White, yellow, dark green, and other options. After the galvanized steel surface is finished, the steel features an excellent rust resistance and corrosion resistance.

Primary purpose: These pipes are often used as automotive precision steel pipes, with a finish specifically for corrosion resistance as required by users.

How do we ensure the quality of these automotive steel pipes?

1. We use high quality raw materials. All raw materials are supplied from internationally known steel plants.

2. Each batch of raw material is checked for both chemical and mechanical properties, according to specifications.

3. During the cold drawing process, our inspectors check every bundle three times: once at the beginning of the process, once during the middle, and finally, at the end of the cold drawing process.

4. During the final heat treatment, every bundle has the surface checked, as well as mechanical properties through sampling.

5. Non-destructive testing machinery and manual inspection ensure the 100% quality rate.