Oil Immersed Transformers

Oil immersed transformers produced by South China Electric mainly include power transformers and special transformers. The range of these transformers is 0-35kV and 0-20,000 kVA. In addition, our oil immersed distribution transformers are produced in strict compliance with the IEC60076 international power transformer standard.

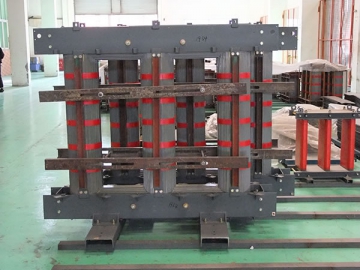

Cores

According to different adopted material and structure, there are totally three core types: laminated silicon steel core structure, silicon steel wound core structure and amorphous alloy core structure. All of our products use cold-rolled grain oriented (CRGO) silicon steel as a magnetic conductive material and adopt a multiple-step laminated structure. The amorphous alloy core is produced from high quality amorphous alloy materials, mainly used in low-loss distribution transformer of 0-1,600 kVA.

Windings

High and low voltage windings are made of oxygen-free copper wires. High voltage windings have cylinder structure, sectional cylinder structure and pancake winding structure. Low voltage windings have four following structures: cylinder, spiral, foil and pancake structure. We adopt different mode and structure of high and low voltage windings in accordance with the transformer capacity and voltage class as well as the electric, machinery and cooling requirement. By doing this, we ensure a good capacity of our transformers for withstanding voltage surge and short circuit.

Tap changers

Our company provides off load and on load tap changer.

The off load tap changer is suitable for small-capacity transformers. It has two voltage regulating options: 3 and 5 position. This kind of tap changer must be operated when the transformer is de-energized.

The on load tap changer is applicable for large-capacity transformers, especially for those with strong voltage fluctuations. Its voltage regulating range is 7, 9, 11 and 17 position. You can conduct living working with CF, S and V type tap changer.

Tanks

Our oil immersed transformers mainly consist of three types: corrugated tank, barrel-type tank and bell-type tank. The corrugated tank is especially designed for 0-1,600 kVA transformers, barrel-type tank for 2,000-10,000 kVA and bell-type tank for 12,500-20,000 kVA. All tanks utilize the automatic electrical arc welding technique, preventing leakage under various operating condition. In the pretreatment process, the corrugated tank adopts pickling and parkerising technique. When it comes to large-scale tanks, we will adopt sandblasting technique. In the paint spraying process, we adopt three protective layers: primer, middle coating and finishing coat, providing a good capacity of anti-corrosion. If necessary, we also provide hot dip galvanized method according to the working condition. The tank is covered with high quality sealed material and must undergo strict leakage test, offering a strong guarantee of zero leakage. The newly fin radiator and corrugated tank greatly improve the appearance. In addition, clients are able to choose the primer colors.

Bushings

Our porcelain bushings have four voltage ranks: 1kV, 10kV, 20kV and 40.5kV. The elbow cable connector is perfect for use in products with a voltage under 10kV. According to different structure, our bushings can be installed on the transformer cover or tank wall. The terminal intervals can also be set if needed.

Other designs are also available on request.

Standard Accessories

Oil conservator(available on request, usually for transformers above 2,000kVA)

Temperature indicator (for transformers above 1,000 kVA)

Pressure relief valve

Oil level indicator

Oil feeding/drain valve

Oil sample valve

Grounding device

Lifting device

Cable box (available on request)

Tests

All products produced by South China Electric have passed routine test, type test and special test conducted by national labs. All power machines are designed and produced in strict compliance with international standards and client requirement. Non-conforming products will be picked out. The routine tests our oil immersed transformers must undergo are as follows:

Voltage ratio and connection group test

Load loss and short circuit impedance measurement

No-load loss measurement

Power frequency withstand voltage test

Induced over voltage test

On load tap changer test (especially for on load regulating transformers)

Transformer oil test

Tank leakage test

Temperature rise test

Lightning impulse test

Partial discharge measurement

Manufacturing Process

Slitting

Slitting Cores are being laminated

Cores are being laminated Low voltage winding

Low voltage winding

Finished low and high voltage windings

Finished low and high voltage windings High voltage winding

High voltage winding Initial assembly of oil immersed transformers

Initial assembly of oil immersed transformers

The initial assembly is completed

The initial assembly is completed Insulating parts

Insulating parts The final assembly of oil immersed transformers

The final assembly of oil immersed transformers

The final assembly

The final assembly The transformer is feeding oil

The transformer is feeding oil The transformer is being sprayed

The transformer is being sprayed

The spray booth

The spray booth The vacuum drying of our transformers

The vacuum drying of our transformers