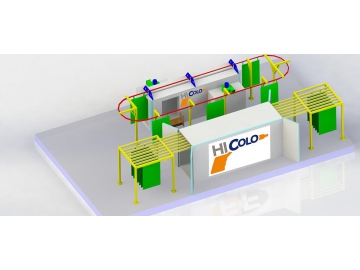

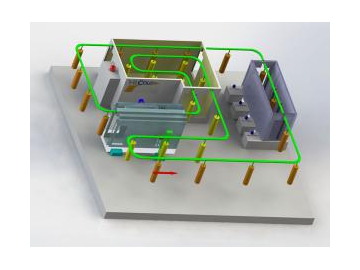

Electrophoretic Coating Line

This electrophoretic coating line is configured with tank, stir and cycle system, electrode device, liquid coating temperature adjusting device, coating supply equipment, ultra filtration device, ventilation device, power supply equipment, washing equipment after electrophoresis, coating storage device, etc.

The electrophoretic coating is a spraying method that utilizes the external electric field to make the pigment, resin and other particles suspending on the electrophoretic liquid to migrate directionally and cumulate on substrate surface of one of the electrode. It is a complicated electrochemical reaction under at least four simultaneous actions in general, like electrolysis, electrophoresis, electro deposition and electro osmosis. This electrophoretic coating is water soluble, nontoxic and easy for automated control. It is extensively accepted in automobile, construction, hardware, home appliance and other industries.

Technological Characteristics

1.This technology chooses the water soluble coating and takes water as the solute to save a large amount of organic solvent. It reduces the air pollution and environmental harm. It is safe, sanitary and gets rid of the hidden danger of fire.

2. This electrophoretic coating line runs with high efficiency, automated continuous production, low loss and its coating utilization reaches 90% to 95%.

3. The electrophoretic coating film is plump, even, flat and smooth. It is able to reach all the parts of the work piece, like lining, depressed part, weld joint, etc. This method gives the solutions to the different coating problems for complicatedly shaped work piece. Compared with the coating film in other spraying technology, this coating film has obviously better hardness, adhesion, corrosive resistance, impact resistance and penetrating quality.

4. The equipment of electrophoretic coating line is complex with high scientific technology and it is suitable for color fixed production.

Parameters Seen from 4 Aspects

1.From the composition of liquid, there are four parameters including the solid content, ash specification, MEQ and organic solvent content.

2. As for the electrophoretic conditions, the liquid temperature, coating voltage and time are important.

3. The PH value and electrical conductivity show the merits of coating liquid.

4. The curing efficiency, maximum current value, thickness of coating film and penetrating quality present the properties of electrophoresis.

Therein, the electrophoretic coating voltage and time, solid content of coating liquid, temperature, PH value and electrical conductivity are the main items for control and management at site.

Related Names

Electrophoretic Painting Machine Manufacturer | Vehicle Part Coating Solution | Household Appliance Painting System