Epoxy Powder Coating

Request a Quote

View All: http://colorpowdercoater.com

Related Names

Powder Coating Manufacturer | Indoor Electrical Appliance Surface Painting | Coating Material

Technical Parameters

| Description | The epoxy powder coating is a kind of thermosetting material made of epoxies, curing agent and pigment. | |

| Proportion | 1.4-1.8g/cm³ It is varied for formula and color. | |

| Granularity measurement | Varies for usage (in average) 99% <100µm 65-70%>32µm | |

| Package | 20kg carton with lining plastic bag | |

| Storage life | Below 30ºC, the product can be stored in the dry conditions for 12 months. After use, all the containers should be sealed again and packed in the original carton. | |

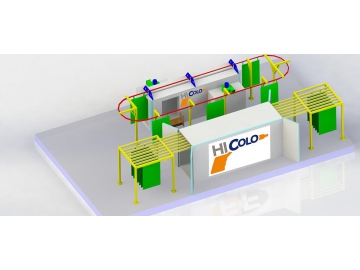

| Usage | Suitable for cooperating with some equipment | Corona electrostatic coating machine Tribomatic charged powder sprayer Electrostatic fluidized bed Fluidized bed |

| Coating thickness | 50-150µm ( varies in different industrial demands) | |

| Coverage rate | 11-13m²/kg, thickness is 60µm It is changed for different types and colors. | |

| Calculating formula of coverage rate | Proportion × Coating thickness = g/m² | |

| Softening temperature | 75-95ºC (Kofler method) It is changed for different types and colors. | |

| Baking conditions | Referring to the temperature of work piece | Low temperature curing: for 20 minutes at 160ºC Common curing: for 15 minutes at 180ºC Fast curing: for 8 minutes at 200ºC Matte coating: for 10 minutes at 200ºC |

| Appearance | The luster is measured by 60º admeasuring apparatus in accordance with ISO2813orGB/T9754-88. | |

| Luster | High gloss type: >85% Semi-gloss type: 40-60% Plain gloss type: 30±5% Customers can consult our technology and sales department about specifications and other relevant information. | |

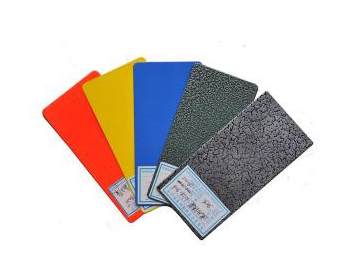

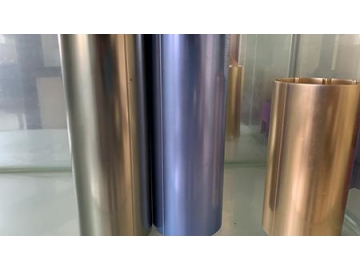

| Effect | Smooth, wrinkle, special effect or as required. This product can be supplied according to the regulations for samples. | |

| Mechanical property | In the lab, the oil removing ferrous phosphide is used in all the experiments to test the samples, whose thickness is 60 to 80µm. | |

| Pencil hardness | GB/T6739-86: H-2H | |

| Adhesion | GB/T9286-88: 0-1 level | |

| Bending test (cylinder axis) | GB/T6742: 0 | |

| Cupping test | 7mm or varied in different colors and formula. | |

| Impact test | GB/T1732-93 : 50kg /cm | |

| Corrosive resistance | Degreasing zinc phosphide is adopted for testing samples, whose thickness is 100 to 120µm. All the experiments are finished in the lab. | |

| Salt spray test | GB/T1771-91: After 500 hours, the product has some faults but the erosion on cross section is less than 2mm. | |

| Damp heat test | Bs.3900Part F2 1973: 5000 hours later GB1740/79(89): after 1000 hours, the coating has no fault except slight gloss loss. | |

| Application range | Office furniture, workshop equipment, door and window frames, home appliances, automobile parts, toys, machinery, etc. | |

| Note | This product is not recommended to be used outdoors. Its durability is not good and it will come across color changing, fading, chalking and other problems. | |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos