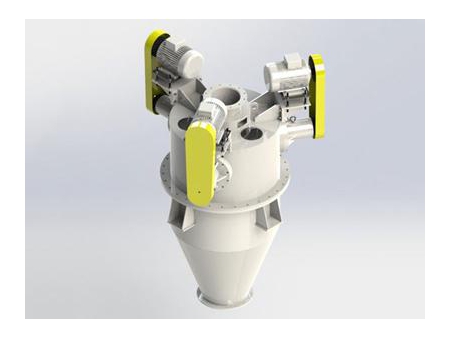

Vertical Pre-Grinding Mill

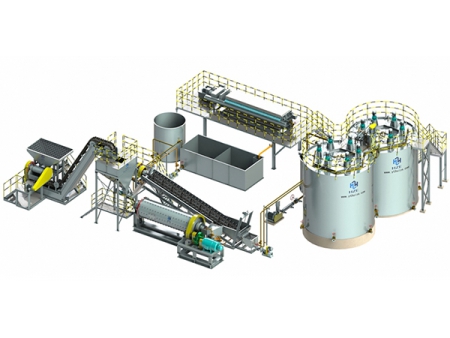

The VPM series vertical pre-grinding mill is equipped with a grinding wheel and three rollers. The rollers are driven by a hydraulic cylinder to symmetrically rotate with high downward pressure against the grinding wheel, so as to shear, crush, and grind the feeding material on the wheel. If used with a ball mill together, it can create a cycled grinding system to fulfill pre-grinding, powder classifying and pre-grinding, as well as final grinding tasks. The electricity consumption can be reduced by 30%-40%, and the productivity can be increased by 50%-100%. Therefore, the pre-grinding machine is your ideal choice to achieve the high productivity and low energy consumption.

Construction and Working Principle

The vertical pre-grinding mill is primarily composed of the electric motor, speed reducer, grinding wheel, grinding roller, hydraulic system, and the lubrication system. The feeding material is firstly delivered to the middle of the grinding wheel. When the grinding wheel rotates, the materials are thrown to the grinding area due to the centrifugal force, and then are pressed and ground by the grinding rollers. Ground materials finally fall down to the lower chamber of the machine, and discharged with the help of a material scraper.

Features

1. The forced lubrication method for grinding rollers can effectively avoid dust entering into bearings. Meanwhile, the vertical pre-grinding mill adopts a double sealing mechanism that is forced ventilation type air sealing, and framework oil seal.

2. The grinding wheel lining plate and the grinding roller cover are both made of high chromium cast iron, so they offer long lifespan over 30,000 hours, and are easy for replacement.

3. The speed reducer adopts the hydrostatic lubrication system, and imposes sensor monitoring on the oil pressure and oil temperature of thrust bearing bush. Thus, the operation stability is ensured.

4. The hydraulic oil station employs advanced follow-up control system to offer continuous inspection on the equipment operation status, so as to improve the system working status and extend the service life of system components.

5. High productivity but low energy consumption. The vertical pre-grinding mill makes use of pressing force and shearing force for material grinding. It offers better grinding results than roller mills. When used for cement raw material and cement clinker pre-grinding, the pre-grinding machine can increase production capacity by 100% and 50%, respectively, while reducing electricity consumption by 30%-40%. It can be used in combination with a ball mill to form a grinding system with large particle size adjustment range, and the system can ensure enhanced cement compressive strength.

| Item | Unit | Technical Parameter | |||

| Model | VPM-1700 | VPM-1900 | VPM-2100 | VPM-2400 | |

| Effective diameter of grinding wheel | mm | 1700 | 1900 | 2100 | 2400 |

| Used for clinker | |||||

| Material feeding capacity | T/h | 200~230 | 280~320 | 360~410 | 550~600 |

| Power of motor | Kw | 950 | 1350 | 1650 | 2200 |

| End product particle size ( ≤ 0.08mm ) | ≥ 25% | ||||

| End product particle size ( ≤ 2mm ) | ≥ 85% | ||||

| Used for cement raw material | |||||

| Material feeding capacity | T/h | 240~270 | 320~360 | 420~480 | 620~700 |

| Power of motor | Kw | 800 | 1000 | 1350 | 1900 |

Related Names

Crushing Mill | Roll Grinding Machine | High Pressure Grinder