Thermal Spray Coating for Piston Rod

Advantages of ceramic coating over chrome plating exist in a large number. Several of them are listed below.

Extended Service Life

1. The ceramic coated piston rod is highly resistant to corrosion. Enhanced corrosion resistance means a longer use life of the cylinder.

2. Tested for corrosion resistance with a salt spray test, the ceramic coated piston rod generally has a use life of over 1500 hours, which is five to six times the lifespan of an ordinary chrome plated rod. This makes our rod ideally suitable for demanding applications, such as in the chemical contaminant or corrosive seawater environment.

High Strength, Wear Resistance, and Smooth Surface Finish

After ceramic coating, a strong binding force of over 30MPa is formed between the coat and the rod surface. The rod has a surface hardness exceeding 700HV, along with exceptional tensile strength and surface roughness up to Ra0.20.

CPMS Sensor for High-Precision, Maximum Protection, and Easy Maintenance

The CPMS sensor is located on the piston rod. Its function is to indicate the amount of rod extension throughout the range of its stroke. With a positioning accuracy of ±1mm, the sensor proves to be waterproof after being submerged under water at a depth of 10 meters for 30 days. Directly installed on the sealed end cap of the cylinder, the sensor can be removed from the cylinder without changing the position of any other parts during maintenance and repair.

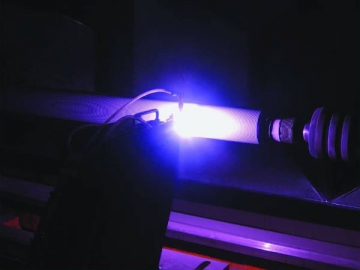

Advanced Hot Spray Painting Technology

The hot spray painting technology came into use in 1940s. From 1990s onwards, it began to gain widespread acceptance. Now it is commonly used by military, aerospace, textile, machinery, electricity generation, and biological engineering industries.

The hot spray painting process starts with the paint being heated to a molten state. Then high-speed jets of air spread the molten paint onto the rod surface to create a high-quality coat.

Ceramic coating has many advantages compared to chrome plating. It has better strength and surface hardness, resists extreme temperatures, and contains minimum pollutants.

The use of ceramic coating to the rod surface satisfies various properties and requirements for the piston rod.

Ceramic Coating Properties

Depending on the type of ceramic power, the ceramic coat can be divided into two types: ordinary TCT1.0 and Metal-Ceramic TCT2.0.

| Serial Number | Items | Parameters |

| 1 | Base Metal | Carbon steel or alloy steel |

| 2 | Primer and Thickness | NiCr, 60~100um |

| 3 | Topcoat and Thickness | Al2O3 or Cr2O3, ≥200um |

| 4 | Surface Hardness | ≥750HV |

| 5 | Surface Roughness | ≤Ra0.25 |

| 6 | Salt Spray Testing Time | ≥1500h |

| 7 | Ambient Temperature Range | -35~ 80°C |

| 8 | Impact Force | ≥2.5J |

| 9 | Binding Force with Base Metal | ≥30N/mm2 |

| 10 | Porosity | <1~2%, Surface or Deep Hole Sealing |

| Serial Number | Items | Parameters |

| 1 | Base Metal | Carbon steel or alloy steel |

| 2 | Primer and Thickness | Self-fluxing alloy, ≥100um |

| 3 | Topcoat and Thickness | Metal matrix composite carbide, ≥200um |

| 4 | Surface Hardness | ≥700HV |

| 5 | Surface Roughness | ≤Ra0.20 |

| 6 | Salt Spray Testing Time | ≥2000h |

| 7 | Ambient Temperature Range | -40~ 120°C |

| 8 | Impact Force | ≥80J |

| 9 | Binding Force with Base Metal | ≥40N/mm2 |

| 10 | Porosity | <1~2%, Surface or Deep Hole Sealing |

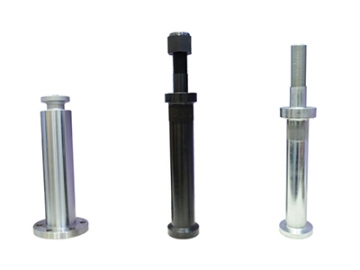

We have made many ceramic coated piston rods. For detailed order information, please refer to .

Related Names

Ceramic Coated Piston Rod | Hydraulic Cylinder Rod | Connecting Rod