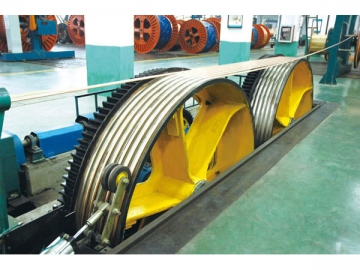

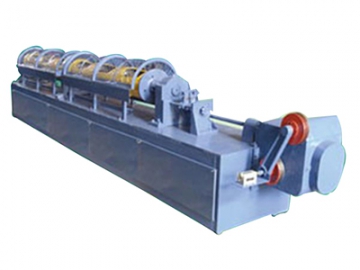

JLK Rigid Strander

Applications

The rigid strander is generally employed for stranding aluminum wire and copper wire. Apart from that, it can be used for making round or sector-shaped compact conductor, as well as wire coils of Milliken conductor.

Features

1. The frame of this rigid stranding machine is integrally welded and bored.

2. It can synchronously strand multiple cable cores.

3. The bobbins are loaded and unloaded in batch.

4. Our cable making machine is suitable for the production of Milliken conductors.

Advantages

1. High Speed

The rigid strander applies 630/6B cage, maximum rotation speed of which reaches 350rpm.

2. Multiple Sizes

Its bobbin diameter ranges from 400mm to 800mm. Bobbin amount of each single cage is from 6 to 48. The bobbins are arranged in 3, 4, 5, or 6 equations.

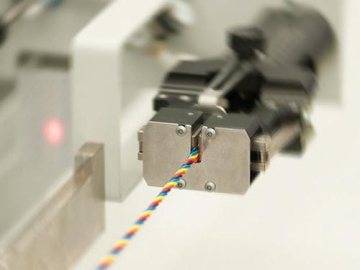

3. Multiple Tension Modes

A variety of tension modes are available. There are magnetic tension, mechanical tension, mechanical with feedback tension, pneumatic tension, etc.

4. Different Batch Loading Methods for Bobbins

Several kinds of batch loading can be selected, e.g. hydraulic or electric side-bottom loading device, side loading device, etc.

5. Diversified Clamping Mechanism

Manual clamping, pneumatic clamping, electric clamping, and other clamping devices are optional.

Improvement

1. Frame holes of the machine unit are specially designed to ensure the concentricity. This design prevents the tension from being affected.

2. The rigid stranding equipment is optimized in the clamping mechanism. The stable pneumatic tension is thereby enhanced, and the bearing clamping is more reliable.

3. The transmission gear is machined with grinding technology. It produces little noise.

4. To make sure the machining precision and convenient adjustment of synchronous belt, we have optimized the installation structure of the synchronous belt transmission.

5. New type of hydraulic side-bottom loading device is developed.

6. The rigid strander is added with a new electric clamping mechanism.

Sales Performance

In 1996, the first rigid stranding machine was sold to Hebei Province, China. Many sets of such equipment have been exported to many foreign courtiers.

| Abu Dhabi: 1pc Algeria: 3pcs Egypt: 6pcs Russia: 1pc Korea: 8pcs Malaysia: 6pcs | Bangladesh: 1pc Mexico: 4pcs Nepal: 1pc Sudan: 1pc Tajikistan: 1pc Thailand: 1pc | Turkey: 3pcs Uruguay: 1pc Iran: 9pcs India: 15pcs Indonesia: 6pcs Vietnam:4pcs |

| Bobbin size (mm) | Max. rotation speed (rpm) | Wire dia.(mm) | |||||||

| 6B | 12B | 18B | 24B | 30B | 36B | Aluminum | Copper | ||

| 500 | 273 | 225 | 198 | 173 | 151 | 120 | 1.8-5.0 | - | |

| 242 | 199 | 175 | 153 | 133 | 96 | - | 1.2-5.0 | ||

| 630 | Normal speed | 215 | 189 | 166 | 146 | 130 | 103 | 1.8~5.0 | - |

| 190 | 167 | 147 | 129 | 115 | 82 | - | 1.2-5.0 | ||

| High speed | 325 | 290 | 250 | 215 | 185 | 135 | 1.8-5.0 | - | |

| 220 | 195 | 170 | 145 | 128 | 108 | - | 1.2-5.0 | ||