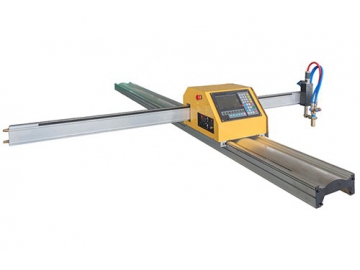

Double Sided Driven CNC Flame Cutting Machine

Description

The double sided driven CNC flame cutting machine is the very first machine we launched after BODA was founded. Its stability is quite satisfactory. This machine is typically suitable for the cutting of carbon steel plate with a width of 1500-9000 mm and a thickness of 6-300 mm. It is equipped with imported CNC system and driving system. The operation is quite simple. The once forming workpiece has great quality and doesn’t need further process, making this metal cutting machine an ideal choice for clients who want to cut thick steel sheet.

The double sided driven CNC flame cutting machine is mainly used for sheet metal machining, engineering machine, steel structure of building, high-pressure container, petrochemical equipment, environmental protection equipment, ship, automobile, coal mining equipment, tower crane machine, and so on.

Advantage

1. The cutting torch holder has been awarded the certificate of "National appearance design patent".

2. The cutting torch lifting structure has been granted the "utility model patent certificate of China"

3. The cutting torch holder has been granted the "utility model patent certificate of China"

4. Stable and precise operation.

This machine comes with a longitudinal running trolley. The rack and pinion transmission device is used at both side of the machine, ensuring the stability and precision of the cutting machine.

5. Stable and reliable structure and long service life.

The cross beam of the double sided driven CNC flame cutting machine adopts rectangle pipe which is made of Q235 steel. For a gantry with a span over 6 meters, the cross beam will be made of two rectangles to increase its toughness, strength and service life.

6. Precise transverse moving station.

It is driven by a steel belt, and moves on bearings. Multi-group workpieces in the same shape or mirror symmetry can be produced at the same time. The precision is quite desirable and resistance is very low. The repairing and maintenance of this kind of steel plate processing machine are also quite simple.

7. Limited pollution.

The flame cutting process produce limited pollution, such as smoke, dust and irritant gas.

8. High-quality longitudinal rail.

We use U71 Mn for the longitudinal rail of the double sided driven CNC flame cutting machine, and use the self-developed three side CNC milling machine for precise milling. So the rail has great smoothness, excellent anti-wear performance, and high toughness. Besides, a rail scraping system is installed on the rail to clear out objects on the rail. Thus the moving precision of the machine is guaranteed.

| Transverse rail interval | 2500-10000 mm |

| Effective cutting width | 1500-9000 mm |

| Driven method | Double sided AC servo motor; Rack and pinion transmission system |

| Effective cutting length | 3000 mm less than the rail length |

| Idle running speed | ≤12000 mm/min |

| Cutting speed | 100-750 mm/min |

| CNC system | BODA CNC or imported CNC system |

| Cutting torch number | 1-12 PCS |

| Minimum cutting torch interval | 200 mm |

| Cutting thickness | 6-300 mm |

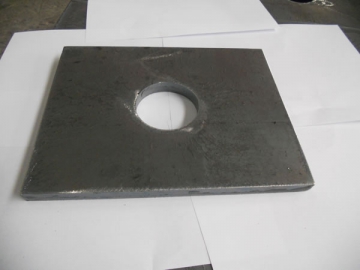

Cutting sample