KJG Paddle Dryer

Overview

The KJG paddle dryer enables continuous drying via heat conduction and horizontal mixing. It earns this name for its mixing blade just looks like paddle. It is also known as mixing dryer at abroad.

As this paddle drying equipment adopts indirect heating, gas is unneeded or merely a small amount of gas is needed for dehydration. Hence, heat volume carried off by airflow is reduced and heat utilization rate is increased.

Lemar develops the paddle dryer through integrating advanced technologies and independent innovation. Except drying, this machine is also capable of cooling, heating, sterilizing, response, low-temperature calcination and other operations. Meanwhile, wedge-type mixing blade boasts high heat transfer efficiency and remarkable self-cleaning capability.

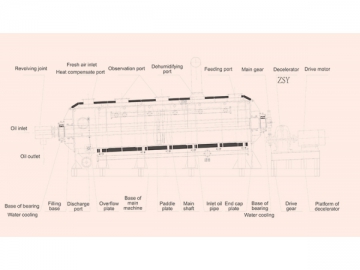

Structure

The horizontal paddle dryer can be fitted with single, double or four shafts. The double-shaft type is composed of W-type housing, top cover, two hollow shafts with blade, end covers, rotating joint, flexible metal hose, gear and sprocket drive mechanism, and also other components.

The two hollow shafts with hollow mixing blade are the most essential parts for this machine. The blade is designed in wedge-type hollow arch shape for heating medium inlet. In addition to mixing function, it also enables heat transfer. Due to its two heat transferring slope sides, material particles promptly slide off the slope surface with blade rotation, and constantly rotary material surfaces intensify heat transfer. What’s more, triangular blade bottom is configured with scraper to remove deposited materials and thereby to guard against dead space engendering.

Blade arrangement and component dimension are designed according to specific requirements. In addition, feed unit, drying unit and material discharge unit of the paddle dryer are equipped with auxiliary mechanism to ensure stable operating performance and drying uniformity. Furthermore, residence time of material is adjustable.

Features

1. Our paddle dryer comes with compact structure, large effective heat transfer area, small floor space as well as high operating flexibility and reliability. It also boasts mixing uniformity, high thermal efficiency, excellent drying effect, low energy consumption, less operational cost, small dust carrying quantity and less material loss.

3. Blade shafts enable intermeshing and self-cleaning, preventing material from sticking to the wall of paddle type dryer.

4. Thanks to indirect heating, material won’t be readily polluted.

5. Product shape and property won’t be affected due to low blade rotating speed.

Application

Presently, this energy-saving equipment is extensively applied to petrochemical, chemical engineering, metallurgy, food, medicine, pesticide and many other industries for drying powdery, granular, caky, pasty or serous materials.

1. Calcining

With heat transfer oil as thermal medium, our paddle dryer can realize low temperature calcining. For example, after calcination, calcium sulphate dehydrate (CaSO4·2H2O) can be transformed into calcium sulfate hemihydrate (CaSO4·1/2H2O), and sodium bicarbonate (NaHCO3) can be transformed into sodium carbonate (Na2CO3).

2. Cooling

By utilizing water or cooled saline water, this drying machine can be used to cool sodium bicarbonate, titanium dioxide powder, ferro-nickel powder and other granular materials, which saves energy, avoids tail gas treatment and also reduces operational costs. Specifically, material temperature can be lowered from 1000°C to less than 40°C after material cooling.

3. Nonuse of hot air

Our paddle dryer does not use hot air, making solvent recovery, energy consumption and environment control tractable and simple. It especially suits for solvent needing recovery as well as combustible, readily oxidized and heat sensitive materials.

4. Heating and melting

With uniform temperature and humidity among axial intervals, this equipment can also be used for heating, melting or solid material reaction, which has been successfully applied to compound fertilizer and modified starch industries. Besides, it also enables food and flour sterilization.

Applicable Industries

Our paddle dryer is widely applied in following industries:

1. Petrochemical

Polyolefin powder, panlite, high and low density polyethylene, linear ow density polyethylene, polyacetal granule, nylon 6, nylon 66, nylon 12, cellulose acetate fiber, polyphenylene sulfide, allyl resin, engineering plastics, polyvinyl chloride, polyving akohol, polystyrene, polypropylene, polyester, polyformaldehyde, styrene-acrylonitrile copolymer, ethylene-propylene copolymer

2. Environmental protection

PTA sludge, coal ash, electroplated sewage sludge, boiler soot, waste residue of pharmaceutical factory, waste residue of sugar refinery, waste residue of gourmet powder factory

3. Feed

Soy residue, bone-based feed, stillage, food scraps, apple pomace, orange peel, bean pulp, chicken bone feed, fish meal, feed additives, biont residue

4. Food

Starch, cacao bean, niblet, salt, modified starch, drup

5. Chemical

Sodium carbonate, nitrogen-phosphorus-potassium mixed fertilizer, kaolin, bentonite, silicon dioxide, soot carbon, ardealite, oxidized sodium fluoride, calcium nitrate, magnesium carbonate, sodium cyanide, aluminium hydroxide, barium sulfate, calcium sulfate, calcium carbonate, dyestuff, molecular sieve, saponin