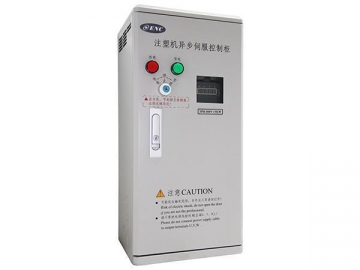

Frequency Inverter (Energy Savings with Variable Speed Drive)

Unique to KE610 frequency inverter is the bypass circuit which keeps the motor up and running in the event of drive failure. Built on the basis of KE600 series closed loop vector control variable frequency drive, KE610 frequency converter delivers significant energy savings to motor users. In the case of VFD replacement, users can switch the drive to the bypass mode which allows the motor to operate continuously and maximize its uptime.

With KE610 frequency inverter, high reliability, soft start and easy operation can be assured. This energy-saving VFD is widely used on injection molding machines, escalators, and air compressors for energy conservation. The rate of energy saving is about 25% to 65% when this AC drive is used on an injection molding machine.

Product Features

1. This energy saving frequency inverter is integrated with V/f control, open loop vector control, close loop vector control and torque control.

2. Optimized identification model of motor parameters efficiently reduces sensitivity of the inverter on motor parameters, yielding more accurate auto-tuning.

3. The adjustable-frequency drive is designed with high starting torque. As a result, the frequency inverter is able to provide 150% torque with 0.5Hz under open loop vector control mode and 180% torque with 0Hz under close loop vector control mode.

4. This motor speed controller features fast, dynamic response to sudden changes in load torques. Its dynamic response time is less than 20ms under open loop vector control mode and is less than 5ms under close loop vector control mode.

5. Our variable frequency drive has powerful ability to resist current surge. Great vector control characteristics make sure that the inverter can continue to work and doesn’t trip even with heavy load. This AC drive is able to run with overload and 200% rated current for 3 seconds.

6. The frequency inverter has a high power factor and low reactive power loss. There is no large current impact when it starts.

7. With a built-in PID controller, the frequency inverter is convenient to form a closed loop control system to control process variables like temperature, pressure and flow.

8. The frequency inverter manages to automatically reset in times of faults or power failure, thus ensuring continuous production and high production efficiency.

9. Advanced power module driving mode is adopted. Also, the variable-speed drives with power higher than 18.5kW are designed with built-in DC reactance to increase power factor and efficiently inhibit harmonic wave, eliminating disturbances of the inverter on the variable frequency system.

10. Self-lock function in case of faults ensures safety of devices.

11. Design of two-circuit of power frequency/variable frequency leads to continuous operation and makes production free from influence.

Technical Parameters

For detailed technical parameters, please check KE600 series variable frequency drive in link

Model Selection

| KE600 | KE610 | |

| Power Range | 1.5~630KW | 7.5~132KW |

| Bypass Function | NO | YES |

Model Selection

KE610 frequency inverter is exclusively used in injection molding machines can be provide with the voltage of AC 380V. Its power ranges from 7.5 kW to 75kW.

| Type | Voltage Classes | Matched Motor | Rated Input Current(A) | Rated Output Current(A) | |

| kW | HP | ||||

| 380 | 7.5 | 10 | 26 | 25 | |

| 380 | 11 | 15 | 35 | 32 | |

| 380 | 15 | 20 | 38 | 37 | |

| 380 | 18.5 | 25 | 46 | 45 | |

| 380 | 22 | 30 | 62 | 60 | |

| 380 | 30 | 40 | 76 | 75 | |

| 380 | 37 | 50 | 92 | 90 | |

| 380 | 45 | 60 | 112 | 110 | |

| 380 | For customized products, please contact Micno for relevant information. | ||||

| Type | Matched Motor | Rated Input Current | Rated Output Current | |

| kW | HP | (A) | (A) | |

| 7.5 | 10 | 26 | 25 | |

| 11 | 15 | 35 | 32 | |

| 15 | 20 | 38 | 37 | |

| 18.5 | 25 | 46 | 45 | |

| 22 | 30 | 62 | 60 | |

| 30 | 40 | 76 | 75 | |

| 37 | 50 | 92 | 90 | |

| 45 | 60 | 112 | 110 | |

| 55 | 75 | 157 | 150 | |

| 75 | 100 | 180 | 176 | |

| 90 | 120 | 214 | 210 | |

| 110 | 150 | 256 | 253 | |

| 132 | 180 | 307 | 304 | |

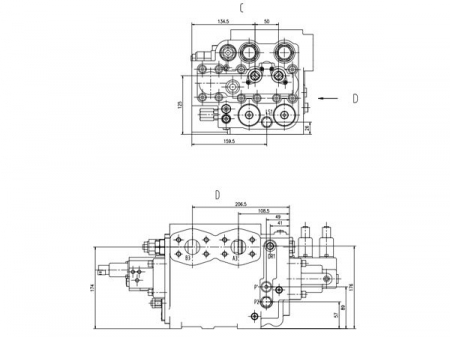

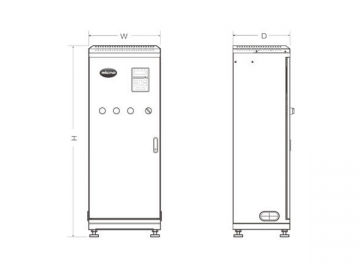

Overall Dimensions

Limited by space, only part of types is displayed. For more information of types and dimensions, please check Product Catalog in link or KE600 User Manual.

| Power Range (kW) | W(mm) | H(mm) | D(mm) |

| 7.5~15 | 270 | 752 | 230 |

| 18.5~30 | 330 | 922 | 263 |

| 37~45 | 380 | 1065 | 350 |

| 55~75 | For customized products, please contact Micno for relevant information. | ||

Applications

The energy saving variable frequency drive is widely used in injection molding machines, escalators, air compressors, belt conveyors and CNC machines.

1. Compatible with injection molding machine of mainstream brands, the variable frequency drive achieves outstanding performance beyond imagination.

2. KE610 variable frequency drive can also be used in escalators, central air conditioners and occasions in need of switch between power frequency mode and variable frequency mode.