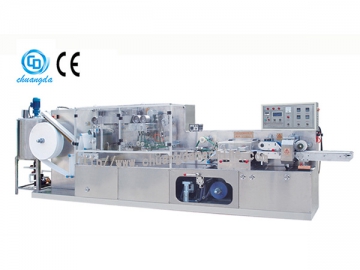

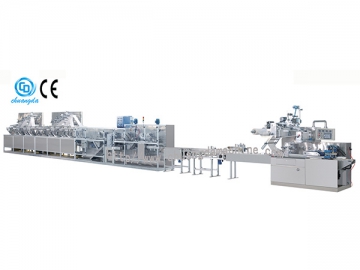

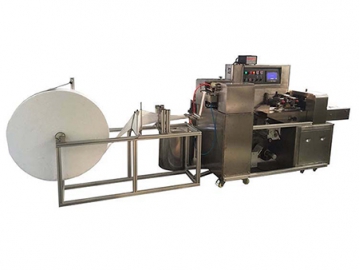

CD-160II 1~2pcs Automatic Wet Wipe Machine

Detailed Product Description

Our CD-160II 1 or 2pcs automatic wet wipe machine offers automatic unrolling and folding of coiled raw paper, liquid adding, cutting and packing performance. The whole process is finished on this wipe converting machine automatically, sanitarily at high speed

Main Features

1. This automatic wet wipe machine is designed with touch screen, through which users can set the length of package bag and adjust the pattern position of the package bag directly without stopping the machine.

2. If the length of the wet wipe needs to be modulated, users can operate it on the machine directly without changing any spare part. This wet tissue packing machine is operation friendly.

3. There is an electric differential device mounted in our wet wipe equipment for positioning the wet tissue and packaging bag. During this process, this paper converting machine needs no stop at all so that the production schedule keeps normally.

4. This automatic wet wipe machine is able to make single piece or double pieces of wipes packed flexibly to meet specific needs of customers.

| Electrical source | 380V, 50Hz |

| Total power | 6kw |

| Production speed | 1. piece: 80-150 packs/min. 2 .pieces: 40-90 packs/min. |

| Product size (unfolded) | (120-260)×(150-200)mm (L×W) |

| Product size (folded) | (60-130)×(50-80)mm (L×W) |

| Control system | PLC control system, color touch screen |

| Suitable material | Spunlace non-woven fabric |

| Gross weight of raw material | 40-80g/m2 |

| Size of raw material | (150~200)×Ф1000mm (W×D) |

| Weight of machine | 1800kg |

| Machine size | 5400×1000×1600mm (L×W×H) |

Working Flow

1. Making process

Unrolling the entire coil of raw material→ longitudinal folding in N shape→ humidifying the wipes → adjusting the humidity of wipes→ cutting → folding wipes in V shape → stacking two pieces if the double pieces wipes in one bag are needed → conveying the wet wipes to packing system.

2. Packing process

Unrolling packing film→ printing date on the film→ feeding the wet wipes into the formed bag →sealing the bag in the middle place → finishing the horizontal seals of the bag at both sides→ discharging finished products