LB-1500 Asphalt Mixing Plant (90-120 Ton/h)

With the productivity of 90-120 ton/h, the LB-1500 asphalt mixing plant is appropriate for batch mixing of asphalt material in a variety of construction projects, such as expressway, urban road, airport construction, etc. Our asphalt batch mix plant is of three operating modes, namely automatic, semi-automatic and manual mode, to meet your demands. The material conveyor and asphalt mixer are fitted with automatic warning devices, which facilitates failure checking and guarantees safe operation.

Features

1. The drying drum for the batch mixing system can be fixed with an Italian burner or an advanced domestic burner.

2. The mixing tank of asphalt mixing plant is manufactured from high-quality manganese steel, so as to resist the abrasion of stone material. It enjoys longer service life than ordinary steel mixing tank.

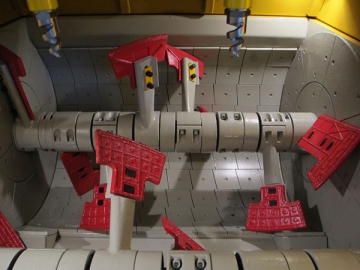

3. The hot mix asphalt plant adopt the modular design, allowing for the direct assembly of its components, including the main machine asphalt mixer, dust setting pocket and so forth. Fastened by screws, these assembly units may be assembled and disassembled easily. The installation procedure will be conducted under the guidance of our two technicians.

4. Its automatic control system is realized on the basis of a computer. It only needs a few operators, effectively reducing labor cost.

5. The asphalt mixing plant makes use of a 4-6 layer linear vibrating screen supporting double-shaft self-synchronizing. Its exterior part is sealed for dust prevention. rock wool is applied to preserve heat and conserve energy.

Parameters

| Model | |

| Productivity | 90-120 ton/h (water content≤5%) |

| Fuel | Diesel, heavy oil, natural gas, coal |

| Cold aggregate framework | Frequency control |

| Drying drum | ¢1800*7000MM |

| Burner | Proportional adjustment |

| Hot aggregate elevator | Centrifugal discharge |

| Vibrating and screening device | Four-stage |

| Metering device | Computer/Aggregate controller |

| Metering precision (static) | Aggregate±0.5% Asphalt, powder±0.25% |

| Mixer | Forcing type |

| Filtering area | 500 M2 |

| Intermittent mixing | 1500KG/batch |

| Mixed material storage | 60T |

| Installed power | 336.2KW |

| Floor area | 32*32M |