Chain Conveyor

- FU chain

- FU chain conveyor

FU chain conveyor is a newly developed product by Haijian introducing advanced technology from Japan and Taiwan, China. It is used to convey powdery and small pump materials horizontally or with 15 degree of incline angle. This chain linked conveying machine is an ideal choice for transporting materials due to the obviously superior performance than screw conveyor, embedded scraper conveyor, and other conveying equipment.

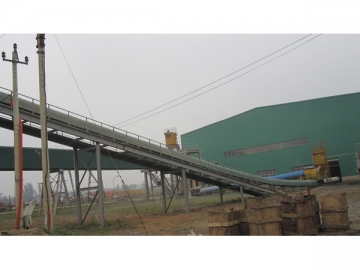

Since being developed, this horizontal chain transporter has won great popularity among domestic and overseas users and found wide applications in a large variety of industries such as building materials, construction, chemical, thermal power, grain processing, mine, machinery, metallurgy, traffic, port and transportation, to name a few.

Characteristics

1. The chain conveyor boasts large conveying capacity, namely 15-500m³/h which ensures that a large number of materials can be conveyed in small space.

2. Compared with the screw conveyor, this user friendly conveying equipment can save 40%-60% power consumption in that it is capable of conveying the materials by virtue of their internal friction.

3. The housing is completely sealed so that the dust can not flow out. Safe operation and reliable running are also ensured.

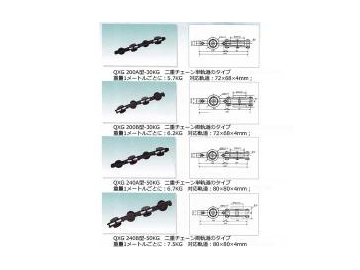

4. Long service life can increase its competitive force. To illustrate, the normal life span of the chain that is made of alloy steel by means of advanced thermal treatment is more than 3 years. According to different materials, the life span of roller on the chain is 1 to 3 years.

5. The chain conveyor features long conveying length. To be specific, the horizontal conveying distance can reach over 60 meters.

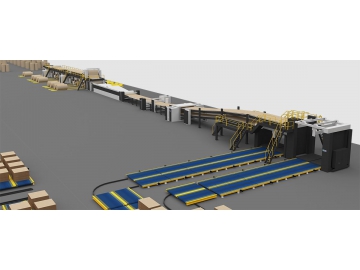

6. Flexible process layout can make the micro object conveyor can be installed at overhead place, on the ground, in a melt pit or on a slope. Additionally, it is favorable for multipoint feeding and discharging.

7. Low cost, durability, low maintenance, low energy consumption and high efficiency can be ensured to secure the users.

Model Selection and Process Layout

The specifications and parameters are showed in form 1 (see form 1 below). In this form, you can see the conveying capacity range under different chain speeds of various models. Same capacity can correspond to different models. When choosing the model with larger capacity, you can get lower chain speed and small wear while higher investment. Conversely, when choosing the model with smaller capacity, faster chain speed and higher wear while more economic investment can be ensured.

It is necessary to point out that, when the practical conveying volume do not reach 65% of the capacity, equipment wear will be worsen because of chain idle running resulted from quite thin material layer in the closed trough. Therefore, it is suggested that practical conveying volume should not be lower than the minimum capacity showed in the form one, and the number got by multiplying 1.2 can not be higher than the maximum capacity.

Technical Parameters| Models | Closed trough width (mm) | The most appropriate conveying capacity (m3/h) | Ideal grain number | Max. particle size(content ≤10%) (mm) | Accepted incline angle | Material humidity | |||||||

| Chain speed (m/min) | |||||||||||||

| 11 | 13.5 | 14 | 17 | 21 | 22 | 27 | 28 | ||||||

| 150 | 6-10 | 10-16 | 13-20 | < 4 | 8 | ≤15° | ≤5% | ||||||

| 200 | 12-18 | 18-28 | 25-38 | < 5 | 10 | ||||||||

| 270 | 22-33 | 26-40 | 33-50 | 45-68 | 54-82 | 86-130 | < 7 | 14 | |||||

| 350 | 43-64 | 54-80 | 66-98 | 120-180 | < 9 | 18 | |||||||

| 410 | 60-90 | 73-110 | 90-135 | < 11 | 21 | ||||||||

| 500 | 80-120 | 105-160 | 140-200 | 180-240 | < 13 | 25 | |||||||

| 600 | 120-160 | 150-220 | 200-290 | 240-360 | < 15 | 30 | |||||||