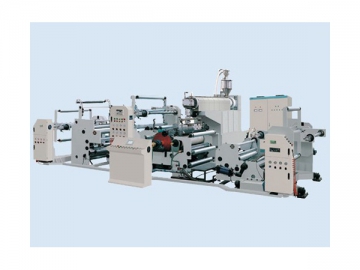

Car Mat Lamination Line

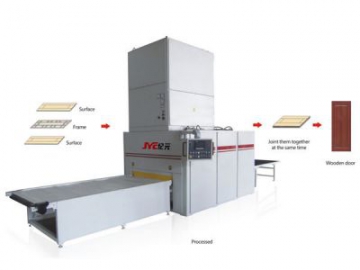

This lamination line is mainly used for lamination of fabrics back to back to produce soundproofing car mat as well as 5-piece embossed cushion cover. Typical advantages of our car mat lamination equipment include reasonable design, compact structure, and easy operation. The car mat products that this lamination line produces have been commonly seen in Fengshen, Bluebird, Honda, and Chery cars.

In an ongoing effort to improve product quality, we have subjected our lamination equipment to the tempering process whereby the excess hardness in those parts are removed. This process also helps the laminated mat production line reduce energy consumption by more than 50%. Mature on-line process and professional electrical control system ensure a long-term stable operation of the car mat lamination line.

Car Mat Backcoating Process Flow

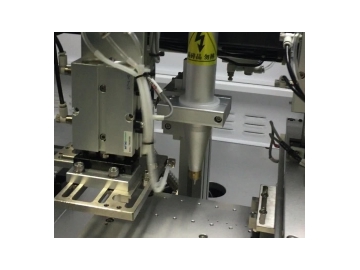

Automatic feeding - hot melt extrusion - rapid change of screen - shape formation in a die - unwinding - automatic deviation control - lamination and shaping - cooling and final profile formation - guide roller - automatically cut to the required length - stacking platform

Technical Specifications

Laminate Width (mm): 1300-3600

Maximum Linear Speed m/min: 4-10

Equipment Specification: SJ110/33-DF1800

Extrusion Lamination Output: 0.5-1.5kg/m2

Annual Production Capacity: 1 million m2

Annual Extrusion Output: 1500t (in 260 days at the rate of 6t /d and 280kg/h)