Non-woven Fabric Cast Film Extrusion Lamination Line

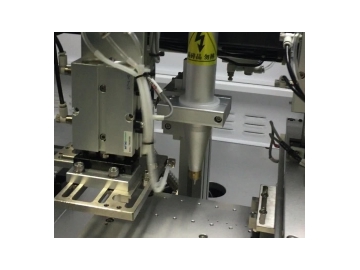

This extrusion lamination line uses an extruder to produce cast stretch film which will then be laminated over the non-woven fabric or thin paper via lamination equipment. After extrusion, membrane materials are guided through the single-long narrow slit by an air flow.

Proven extrusion lamination equipment and technology meet customer requirements for reliable production and long-term operation. From raw stock feeding to final non-woven fabric take-up, there are automatic controls at each step of the way. The AC variable frequency drive technology saves you more electricity and is more reliable than traditional DC speed control system. The touch-screen controller offers easy access to the extrusion laminating process. The whole extrusion lamination line features a proper structure that delivers high efficiency, low consumption, easy operation, and minimum breakdown time.

Technical Specifications

1. Extruder screw: φ100mm, length-diameter ratio: 32:1, material: 38CrMoAl.

2. The extruder screw has been through quenching, tempering, and surface nitridation. There are dedicated mixing and melting zones to ensure the raw plastics are thoroughly mixed and melted. This also ensures large-volume extrusion output.

3. T-shaped die is made of 38CrMoAl, which has been quenched and tempered to ensure maximum toughness and hardness. The die is able to withstand high temperatures without deforming.

4. Completely sealed gear box contains reliable gear sets with hard gear teeth.

5. Digital intelligent temperature control system

6. Applications: 20gsm~100gsm non-woven fabrics and other soft substrates

7. Lamination Raw Material: PE, PP

8. Effective Width of Lamination: 2000~2400mm

9. Lamination Thickness: 0.012~0.030mm (single-layer)

10. Lamination Uniformity: tolerance ±8%

11. Peeling Strength: 3~5N/30mm (according to the specific substrate to be laminated)

12. Maximum Extrusion Output: 280kg/h

13. Designed Speed: 0~100m/min

14. Double unwinding rollers come with the magnetic particle brake to control tension. Maximum diameter of unwound roll: 600mm

15. The extrusion lamination machinery uses 4 take-up rollers with automatic metering functions. Maximum diameter of wound roll: 600mm

16. Pneumatic Winding and Unwinding Shafts: 3inch (φ73mm)

17. Installed Power: 150kw (approximately)

18. Dimension of Extrusion Lamination Line (L×W×H): 8500mm×8800mm×3200mm

19. Total Weight of Extrusion Lamination Line: 16000kg (approximately)