Tube Straightening Machine

Features

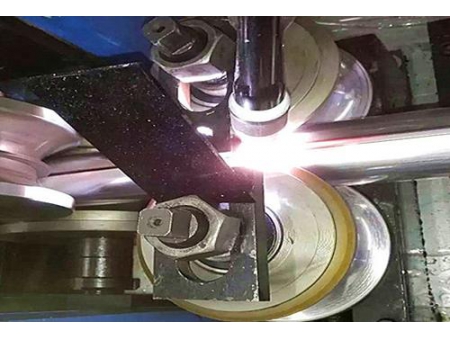

1. The upper and lower machine frames of our tube straightening machine are welded and connected by six vertical posts. The vertical-post structure facilitates machine adjustment and working condition observation.

2. This pipe straightening equipment works flexibly. The straightening rolls are firstly installed on the roll chock. Then the straightening rolls with the roll chock will be fastened to the slide carriage of the upper and lower machine frames with screws. Angel of the straightening rolls can be adjusted according to the diameter of the straightened tube.

3. Gasket is used to control the up and down movement of the slide carriage. This structure makes machine adjustment and maintenance easy.

Application

This tube straightening machine is suitable for strengthening metal tubes (stainless steel tubes, carbon steel tubes and alloy steel tubes) whose diameters are in the range from 114 to 385mm.

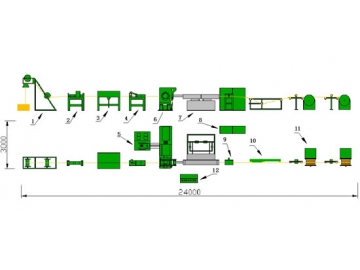

Major components

Our tube leveling machine mainly consists of the upper frame, base, column, seat of lifting roll, lower roll seat, reducer of main motor, universal shaft, and the electric system.

Structure

This is a seven-roll vertical staggered tube straightening machine. The straightening rolls adopt the arrangement mode of 2-2-2-1 and are arranged at a slant in two staggered rows. That means the straightening rolls are arranged angled to the center line of the straightened tubes. Three rolls are distributed in the upper row while the other four rolls are distributed to the lower row.

Dimension and Performance of Tube Straightening Machine

| Order | Item | Technical Parameters | |

| 1 | Maximum yield limit of the straightened tube | 510MPa | |

| 2 | Diameter of the straightened tube | Ф114~Ф385mm | |

| 3 | Maximum wall thickness of the straightened tube | 4~25mm | |

| 4 | Straightening speed | 6~30m/min | |

| 5 | Maximum stroke of the upper rolls | 310mm | |

| 6 | Adjustment range of the lower rolls (manual) | 0~20mm | |

| 7 | Arrangement mode of the straightening rolls | 2 -2 -2 -1 (Staggered) | |

| 8 | Straightness of the straightened tube | 1mm/m | |

| 9 | Minimum length of tube | 4000mm | |

| 10 | Maneuvering lifting speed of the upper rollers | 4.174mm/s | |

| 11 | Adjustment angle range of the straightening rolls (manual) | 28.5 °~33 ° | |

| 12 | Spacing of the straightening rolls | 1050mm | |

| 13 | Throat diameter of straightening roll | 400mm | |

| 14 | Length of the straightening roll | 550mm | |

| 15 | Material of straightening roll | 9Cr2MoV | |

| 16 | Material of the vertical post | 45 # | |

| 17 | Retarder | Velocity ratio | 12.93 |

| Quantity | 2 | ||

| 18 | Main motor | Variable frequency motor power | 75kW/set |

| Revolving speed | 750R/min | ||

| Quantity | 2 | ||

| 19 | Lifting motor for upper rolls | Worm retarder | I=36 |

| Power | 5.5kW | ||

| Revolving speed | 960r/min | ||

| Quantity | 3 | ||

| 20 | Total weight | ≈45t | |

| 21 | Overall dimension (L×W×H) | ≈11.3.×4.5.×3.7m | |