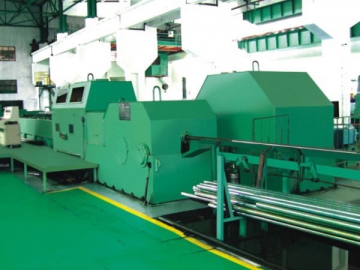

LG60-H Cold Pilger Mill

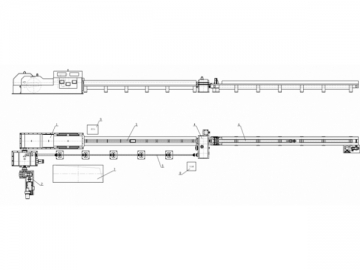

As shown in the figure, a cold pilger mill is usually composed the following parts

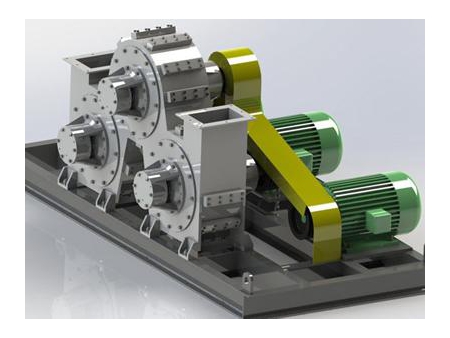

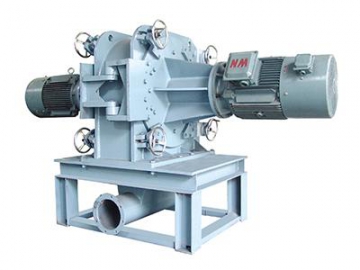

1) the main rolling mechanism, 2) main transmission system, 3) feeding mechanism, 4) rotating feeding box , 5) power distribution mechanism, 6) core bar mechanism, 7) lubrication system , 8) hydraulic system , 9) electrical system.

Features

1. This LG60-H cold pilger mill.he can be used to process highly precise seamless tubes made of ferrous metal and nonferrous metal with diameters in the range from 57mm to 102mm.

2. This cold pilger mill adopts flywheel transmission system. The flywheel transmission system helps save energy and compensate for the inertia force and inertia moment generated by the reciprocating motion of the machine frame. In this way, balance of the whole rolling process is guaranteed.

3. The dual cam structure of our product makes rotation angel adjustable within a certain scope. Hence, our cold pipe rolling machine can meet the requirement of some special processing technologies.

4. Thanks to the side material loading mode, the operator can monitor the working condition of the mandrel in this cold pilger mill while loading materials so as to guarantee inner wall quality of the finished tubes.

Detailed Parameters

| Order | Item | Parameter | Unit | |

| 1 | Hollow tube | Outer diameter | Ф57~Ф102 | mm |

| Wall thickness | 3~15 | mm | ||

| Length | ≤6000 | mm | ||

| 2 | Finished tube | Outer diameter | Ф38~Ф89 | mm |

| Wall thickness | 2~12 | mm | ||

| 3 | Maximum elongation coefficient | Stainless steel≤3 | ||

| 4 | Stroke length of machine frame | 904 | mm | |

| 5 | Stroke number of machine frame | 50~85 | Time/min | |

| 6 | Rotation angle | 31°~26° ( Dual rotation) | ||

| 7 | Feeding amount | 3 ~12 (Dual feed) | mm | |

| 8 | Material loading mode | Side loading | ||

| 9 | Diameter of the roll | Ф370/Ф410 | mm | |

| 10 | Main motor | Model | Z4-250-42 | |

| Power | 160 | kW | ||

| Revolving speed | 1000 | rpm | ||

| Power supply | DC380V | |||

| 11 | Overall dimension | L×W×H | ≈26500×5600×2100 | mm |