LG220-H Cold Pilger Mill

Features

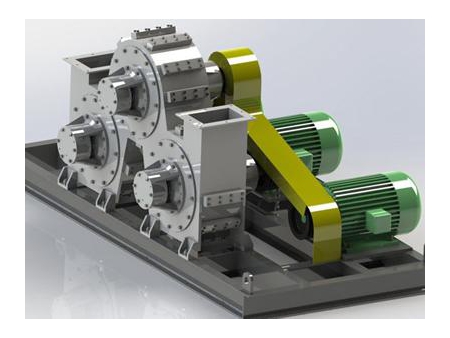

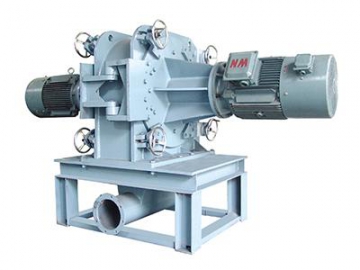

1. Our LG220-H cold pilger mill adopts flywheel transmission system and is configured an operating platform with touch screen. This machine can achieve automatic operation so that is helps reduce cost spent on manual operation.

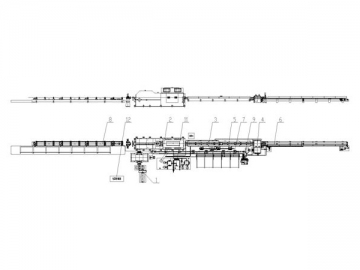

2. The semi-open material unloading channel assembled to our pipe rolling equipment facilitates material discharging condition monitoring and discharging position adjustment.

3. This cold pilger mill can be applied to process ferrous and nonferrous metal seamless tubes whose diameters are in the range of 115~255mm. The pilgered tubes have diameters ranging from 89mm to 219mm.

4. With power of 315kW and revolving speed of 1000rpm, our cold reduction mill has lower energy consumption and higher working efficiency compared with other similar products. With our product, you can save more time and more labor cost.

5. The finished tube chunk applied in our cold pilger mill helps increase quality of the finished tubes.

Detailed Parameters

| Order | Item | Parameter | Unit | |

| 1 | Hollow tube | Outer diameter | Ф115~Ф255 | mm |

| Wall thickness | 6~18 | mm | ||

| Length | ≤8000 | mm | ||

| 2 | Finished tube | Outer diameter | Ф89~Ф219 | mm |

| Wall thickness | 3~15 | mm | ||

| 3 | Maximum elongation coefficient | Stainless steel≤3.5 | ||

| 4 | Stroke length of machine frame | 1123 | mm | |

| 5 | Stroke number of machine frame | 40~75 | Time/min | |

| 6 | Rotation angle | 58° (Dual rotation) | ||

| 7 | Feeding amount | 4~12 (Single feed) | mm | |

| 8 | Material loading mode | Side loading | ||

| 9 | Diameter of the roll | Ф580( Ф650) | mm | |

| 10 | Main motor | Model | Z4-315-12 | |

| Power | 315 | kW | ||

| Revolving speed | 1000 | rpm | ||

| Power supply | 380V | |||

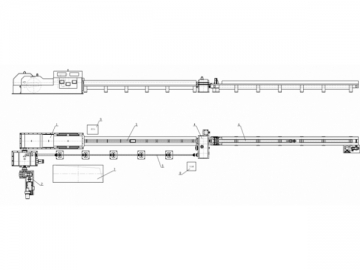

| 11 | Overall dimension | L×W×H | ≈52600×6850×2633 | mm |