CO Removal Catalyst

Our CO removal catalyst is mainly divided into two series which are HHGST02-1 and HHGST02-2. These two models are designed for similar purpose, but they deliver different performance.

Technical Performance

1. The HHGST02-1 CO removal catalyst is able to reduce carbon monoxide content to below 0.5ppm if working temperature and space velocity are within 150-200℃ and 3000-10000h-1, respectively. With a high oxygen-carrying capacity of 50ml/g, it could catalyze the reaction between CO and O2, yielding CO2. In addition, this environment protection catalyst can be regenerated for future use.

2. The HHGST02-2 CO removal catalyst could convert CO into harmless products, and the residual CO concentration is 5ppm or lower. It could work for 120 hours at least for a single operating cycle, and another 3 cycles are available after simple regeneration treatment. The recommended operating conditions are as follows.

a. Temperature: room temperature (≥15℃)

b. Gas humidity: ≤90%

c. Space velocity: 10,000~30,000h-1

Technological Characteristic

1. Before use, the HHGST02-1 CO removal catalyst shall be activated by nitrogen gas at the temperature range of 180-200℃, but fresh air could be heated for activation as well if target gases have a high temperature, such as ones generated by baking oven or fireplace. Then, these target gases are guided to pass through our product, and the best working temperature and space velocity are 200℃ and 1500-3000h-1, respectively. As a result, the residual CO concentration will be reduced to lower than 0.5ppm.

On the other hand, our carbon monoxide cleaning catalyst is able to withstand a high temperature (up to 750℃), and it possesses excellent mechanical strength that allows it to work for 3 years or even longer. In addition, if the concentration of combustible gas is pretty high, a cooling system shall be outfitted to protect our product from sintering.

2. The HHGST02-2 CO removal catalyst is a room temperature catalyst that doesn’t require preheat or activation. It could be fitted into an air purifier for direct use.

Application

1. The HHGST02-1 CO removal catalyst is commonly utilized to remove the small amount of carbon monoxide mixed in oil gas, inert gas, oxygen as well as other gases, and it also fits for low-temperature catalytic combustion of CO, which is necessary for baking oven, fireplace, etc.

2. The HHGST02-2 CO removal catalyst is intended to eliminate CO existed in closed environment, such as underground refuge chambers. Aside from this, it also suits for circumstances where some CO shall be removed, like submarine, respirator, CO2 laser, fuel gas shower, etc.

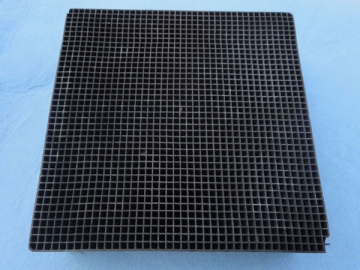

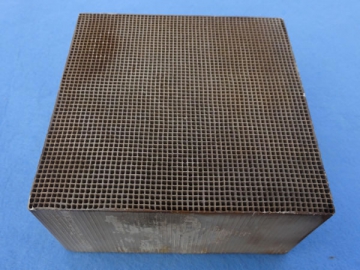

Technical Data of HHGST02-1 CO Removal Catalyst| No. | Item | Specification |

| Carrier: cordierite with coating of composite alumina | ||

| 1 | Space velocity(h-1) | ≥3,000 |

| 2 | Ignition temperature (℃) | 100-150 |

| 3 | Best operating temperature (℃) | 180-200 |

| 4 | Purification rate (%) | ≥98 |

| 5 | Service life (year) | ≥2 |

| 6 | CO concentration at outlet (ppm) | <5 |

| 7 | Bulk density (g/ml) | 0.68±0.05 |

| 8 | Crush strength (MPa) | ≥14 |

| 9 | Coating content (%) | >10.0 |

| 10 | Active component content (%) | 0.1-0.2, or tailored values |

| 11 | Expulsion rate (%) | <1 |

| 12 | Color | Fawn (grey after reduced) |

| 13 | Package | Moisture proof and sealed |

| 14 | Recommended height-diameter ratio | 4:1 for honeycomb ceramic type 2:1 for particle type |

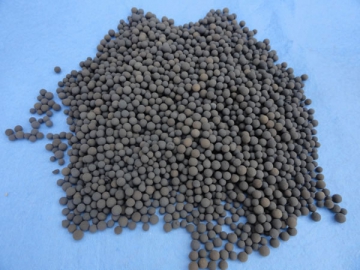

| No. | Item | Specification |

| Composite alumina: Ф2-3mm, Ф3-4mm, Ф4-5mm | ||

| 1 | Space velocity (h-1) | ≥10,000 |

| 2 | Best operating temperature (℃) | Room temperature - 250 |

| 3 | Service life (hour) | ≥360 (continuous) |

| 4 | Bulk density (g/ml) | 0.60±0.2 |

| 5 | Crush strength (N) | ≥60 for Ф2-3mm |

| 6 | Residual CO concentration (ppm) | ≤5.0 |

| 7 | Relative humidity (%) | ≤90 |

| 8 | Active component | Pd, Pt |

| 9 | Purification rate (%) | ≥99 |

| 10 | Color | Grey |

| 11 | Package | Moisture proof and sealed |

| 12 | Recommended height-diameter ratio | ≥1:1 |