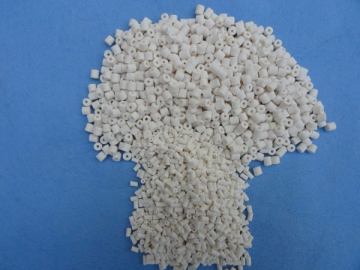

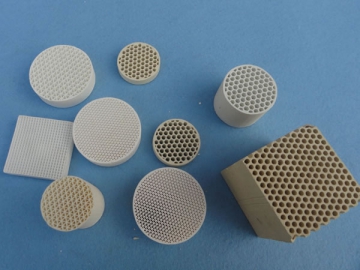

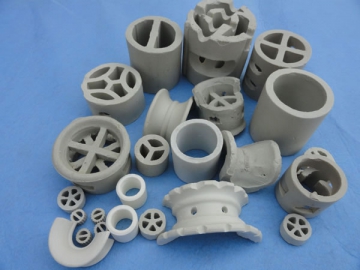

Ceramic Ball

Our ceramic ball is mainly fabricated from commercial alumina and kaolin through shape forming and high temperature calcination processes, and it perfectly protects catalysts due to its good mechanical strength, wide operation temperature range and excellent chemical stability. In particular, the chemical stability makes it extremely resistant to strong acid, strong base and other organic solvents. On the other hand, our silica-alumina catalyst bed support also works as a kind of tower packing, which is considered to be of great significance for quality control in oil refineries.

Standard

National Chemical Industry Standard HG/T 3683.1-2000: Industrial Ceramic Ball, Inert Ceramic Ball

Application

This catalyst support is the perfect packing material for various kinds of reformers, reactors and packed towers used in petrochemical, chemical, fertilizer and environmental industries. Now, it is commonly seen in oil refineries, fertilizer plants, arene plants, methanol plants, ammonia synthesis plants, etc.

| Type | Feldspar | Feldspar-Mullite | Mullite | Mullite-Corundum | Corundum | ||

| Chemical composition | Al2O3 (%) | 20-30 | 30-45 | 45-70 | 70-90 | ≥90 | |

| Al2O3 SiO2 (%) | ≥90 | ||||||

| Fe2O3 (%) | ≤1 | ||||||

| Water adsorption (%) | ≤5 | ||||||

| Acid resistance (%) | ≥98 | ||||||

| Anti-alkalinity (%) | ≥80 | ≥82 | ≥85 | ≥90 | ≥95 | ||

| Thermal stability (°C) | ≥1300 | ≥1400 | ≥1500 | ≥1600 | ≥1700 | ||

| Crush strength (N) | Φ3 | ≥400 | ≥420 | ≥440 | ≥480 | ≥500 | |

| Φ6 | ≥480 | ≥520 | ≥600 | ≥620 | ≥650 | ||

| Φ8 | ≥600 | ≥700 | ≥800 | ≥900 | ≥1000 | ||

| Φ10 | ≥1000 | ≥1100 | ≥1300 | ≥1500 | ≥1800 | ||

| Φ13 | ≥1500 | ≥1600 | ≥1800 | ≥2300 | ≥2600 | ||

| Φ16 | ≥1800 | ≥2000 | ≥2300 | ≥2800 | ≥3200 | ||

| Φ20 | ≥2500 | ≥2800 | ≥3200 | ≥3600 | ≥4000 | ||

| Φ25 | ≥3000 | ≥3200 | ≥3500 | ≥4000 | ≥4500 | ||

| Φ30 | ≥4000 | ≥4500 | ≥5000 | ≥5500 | ≥6000 | ||

| Φ38 | ≥6000 | ≥6500 | ≥7000 | ≥8500 | ≥10000 | ||

| Φ50 | ≥8000 | ≥8500 | ≥9000 | ≥10000 | ≥12000 | ||

| Φ75 | ≥10000 | ≥11000 | ≥12000 | ≥14000 | ≥15000 | ||

| Bulk density (kg/m3) | 1100-1200 | 1200-1300 | 1300-1400 | 1400-1550 | ≥1550 | ||

| Note: The bulk density is for reference only, and should not be taken as the acceptance standard. | |||||||

| Nominal diameter (mm) | Φ6 | Φ8 | Φ10 | Φ13 | Φ16 | Φ20 | Φ25 | Φ30 | Φ38 | Φ50 | Φ60 | Φ75 |

| Diameter tolerance (mm) | ±1.0 | ±1.5 | ±2.0 | ±3.0 | ||||||||

Why Us

1. In Baisheng, the history of ceramic ball production dates back to over 40 years ago, and this long history is a great treasure for us. In fact, our boss’s father participated in drafting relevant national standards when he was young.

2. Aside from long production history, our company is also recognized as the most trustworthy Chinese manufacturer in this field.

3. Thanks to the standardized production flow and complete management system, product quality is strictly controlled as expected. Moreover, attentive service is also what we promise to offer.

4. Our ceramic balls are commonly seen in almost every province (except Tibet) in China. More convincingly, they are also favored by U.S. Steel Corporation and many amous enterprises in Denmark, Japan and other countries.