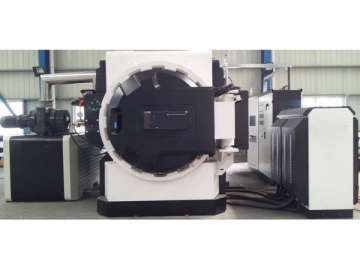

Vacuum Degreasing Furnace

The vacuum degreasing furnace allows you to clean your metals in an ultra fast and complete manner. This kind of metal cleaning system has proved to be ideal for powder metallurgical products and metal injection molding products, including stainless steel, hard alloy, superalloy, high density alloy, ceramic materials, magnetic materials and NdFeB, etc.

Advantage

1. Our vacuum degreasing furnace adopts high efficiency SWEEP-GASTM degreasing system, covering grease collecting, filtering, rough cleaning and fine cleaning.

2. This powder metallurgy equipment is fitted with vapor cleaning system, thus offering thorough degreasing to keep foreign materials absolutely off product surfaces.

3. Computerized control is utilized for temperature and procedure adjustment. Safety interlocking comes with PLC. Therefore, customers avail from interlocking function as well as audile and visual alarm on overpressure, overheat or too high water temperature.

4. Internal circulation system in this vacuum degreasing furnace adopts high efficiency heat exchanging technique to blow workpiece in multiple directions, whereby providing fast and uniformed cooling effect. Comparing with external circulation system, this internal cooling system shows more excellence in terms of space saving, starting temperature and pumping speed.

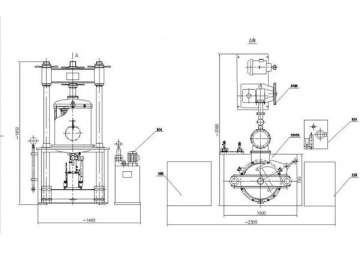

Structure

1. We offer vertical and horizontal layout to cater to your needs. Exclusive sealed furnace and multi-grade water cooled disc type degreaser are employed for astonishing grease removal and collection.

2. Chamber of this vacuum degreasing furnace is built with nickel-chromium system and stainless steel or thermal insulation composite system for extreme performance. Furthermore, the chamber can be removed from the furnace for easy maintenance.

3. Heating system allows for diversified deployments with PID-based independent temperature control.

4. Our vacuum degreaser is fitted with unique vapor cleaning function and internal circulation cooling system, resulting in fast cooling, promoted efficiency and remarkable cleaning.

Technical data| Model | |||||

| Rated feeding capacity (kg) | 50 | 100 | 200 | 300 | 450 |

| Rated furnace temperature (℃) | 950 | 950 | 950 | 950 | 950 |

| Max. furnace temperature (℃) | 1000 | ||||

| Temperature accuracy (℃) | ≤±5 | ||||

| Rated power (kW) | 30 | 60 | 75 | 90 | 120 |

| Rated voltage of power supply (V) | 380 | ||||

| Rated voltage of heating device (V) | Depends on design External transformer is available in all design. | ||||

| Max. vacuum degree (Pa) | ≤6.67 (Empty furnace in cool environment) | ||||

| Pressure rising rate (Pa/24h) | ≤50 | ||||

| Working area dimension (W× H×L) (mm) | 300×300×400 | 300×300×500 | 450×400×670 | 450×400×850 | 600×600×1000 |

| Temperature controlling system | Shimaden programmable controller | ||||

| Vacuum system | Rotary vane vacuum pump | ||||

| Degreasing system | Water ring pump | ||||

Retrofit

1. Build-in fast cooling system

2. PLC and touch-screen display

3. Vapor degreasing system

Related Names

Vacuum Dewaxing Furnace | Vacuum Machine