Mesh Belt Sintering Furnace

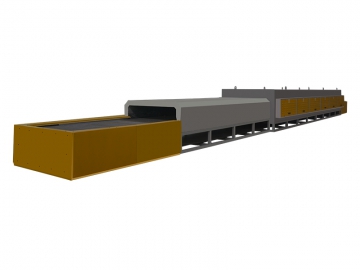

The mesh belt sintering furnace has emerged as an energy effective continuous industrial sintering furnace applicable for pressed iron product, copper product and other related powder metallurgy products. With the aid of shielding gas, flawless sintering treatment is conducted to workpiece at high temperature via scale-free heating and cooling.

Our continuous powder metallurgy equipment finds extensive application in sintering of powder metallurgy products, brazing of all kinds of precise parts, bright annealing of copper alloy parts, magnetic materials and stainless steel products such as tableware, cutting tool and precise products, as well as blackening and bluing of stainless steel heating tubes.

Advantage

1. Superior heat uniformity

Thanks to ingenious hearth design, heat comes from both top and bottom. There is a high rigidity silicon carbide board to control heat uniformity to be ±5℃ and temperature accuracy ±1℃.

2. Low energy consumption

All fiber needlefelt carpet modules provides excellent thermal insulation, low energy storage, reduced heat loss and rapid temperature rising rate.

3. Long service life

Furnace tube on this mesh belt sintering furnace is equipped with pre-pressing system and silicon carbide board at the bottom. This board features high rigidity, low coefficient of friction and considerable resistance to high temperature. As a result, metal tube receives balanced heating, and service life consequently is 1.3 times more than similar products.

4. High automation

Our powder metallurgy sintering furnace acquires intuitive mimic panel and enjoys fully automatic control on temperature and production process. Integrated alarm system and latch-up protection function bring operative safety to a new level.

Structure

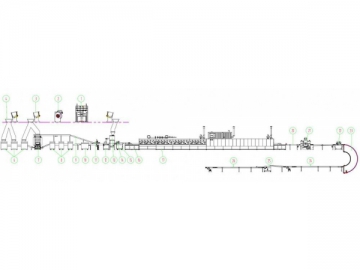

1. This mesh belt sintering furnace mainly consists of feeding unit, heating unit, slow cooling unit, water cooling unit, discharging unit, mesh belt, driving unit, shielding gas unit and electric control unit, etc.

2. Furnace tube is featured with modular all fiber needlefelt carpet on top, ensuring low maintenance, stable thermal insulation and thermal shock resistance, as well as low energy storage and heat loss. Power consumption of induction furnace, temperature rise and heating uniformity are all better than national standard level. As a result, furnace lining enjoys longer service life.

3. Muffle of mesh belt sintering furnace is made up of heat resistant stainless steel and is welded by folded and corrugated steel. Specially enforced structure is designed in accordance with thermal and mechanical principles for longer service life.

4. Electric motor is running with stepless speed regulation and controlled by variable frequency speed regulation. Speed is directly displayed in digital.

5. This mesh belt sintering furnace incorporates with intelligent temperature controller supplied by Shimaden. This device features self-adjustment and standard PID controller, thus preventing temperature overshoot. Digital display readily realizes functions of selection, setting and configuration.

Main heating unit involves the combination of SCR series 3 phase thyristor power controller. In stead of traditional electrical on-off controlling mode, this controller utilizes continuous control not via on-off mode, but on the basis of temperature to automatically adjust heating power.

Additionally, high accuracy and no noise generation can be achieved in temperature control for high power. In addition, there is no influence to internal power system.

Technical data| Model | |||||

| Mesh belt width (mm) | 200 | 300 | 400 | 460 | 610 |

| Heating furnace size (W × H × L) (mm) | 220 × 80 × 6000 | 320 × 80 × 6500 | 420 × 100 × 8300 | 480 × 100 × 9800 | 630 × 125 × 10500 |

| Number of heating zone | 5 | 6 | 6 | 7 | 8 |

| Air consumption (Nm3/h) | 6 | 10 | 16 | 20 | 32 |

| Max. furnace temperature (℃) | 1150 | ||||

| Rated heating power (kW) | 80 | 120 | 160 | 180 | 250 |

| Rated voltage of power supply (V) | 380 | ||||

| Mesh belt speed adjustment | Variable frequency stepless speed regulation | ||||

| Mesh belt material | SUS310S, SUS314S | ||||

| Hearth material | SUS321, SUS310S, silicon nitride bonded silicon carbide | ||||

| Overall dimension (W × H × L) (mm) | 1380 × 1600 × 13900 | 1500 × 1600 × 16500 | 1750 × 1600 × 17600 | 1800 × 1600 × 19000 | 2060 × 1600 × 20000 |

| Temperature control | Shimaden temperature controller | ||||

Retrofit

1. Fuel degreasing system in RBO (rapid burn-off) unit

2. Forced gas quenching system

3. Controller on carbon potential in atmosphere

- Vacuum Gas Atomization Powder Manufacturing Equipment

- Amorphous Alloy Powder Equipment

- Glass Melting Furnace

Related Names

Sintering Machine | Mesh Belt Furnace | Mesh Belt Tempering Furnace