PE/PERT/PPR Water Pipe Extrusion Line

A variable frequency drive is used to facilitate motor speed adjustment so that the speed of our PPR pipe extrusion line matches the output requirement. As a matter of fact, the main electric parts on this extrusion line are all of well-known imported brands.

Unique to our PPR pipe extruder are the barrier screw and high-performance plasticizing system which ensure the extrusion of quality PPR materials at high speed with high shearing force and low plasticizing temperature.

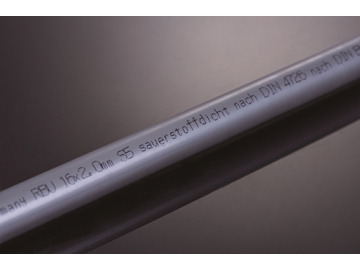

High productivity, stable extrusion, and minimum extrusion error are the main benefits associated with this PPR pipe extrusion equipment. They are also part of the reasons why our PPR pipe extrusion line could become a mainstay in the plastics machinery industry. Available in various diameters and thicknesses, the resultant PPR pipes are also commonly seen in the industrial and domestic water supply system, water transportation and compressed air transportation industries.

For more information, please contact us right now.

Features

1. High-efficiency extruder screw is specially designed to handle PPR materials, which ensures stable extrusion and high extrusion output. Equipped also with the automatic vacuum feeder and drying oven (that dries the pipe at constant temperature), this extrusion line delivers outstanding overall performance.

2. The extrusion die comes with a breaker plate to help maintain a low melt pressure and temperature. A wide range of polyolefin materials can be processed by this extruder to meet your specific production requirements.

3. Haul-off belts are made of abrasion-resistant materials to ensure stable traction at high speed as well as a long service life.

4. The state-of-the-art automatic saw is able to make perfect, chip-free cuts on the finished pipes. The cutting motion of the saw is controlled by a synchronous belt drive which operates very quietly.

| Model No./ Parameters | Range of Pipe Diameter (mm) | Extruder Model No. | Production Rate (m/min) | Maximum Production Capacity (Kg/h) | Installed Capacity (KW) | Dimension (m) | Weight (t) |

| 20-63 | LSJ65/30 | 1-10m/min | 120 | 55 | 32×3.0×2.2 | 9.5 | |

| 75-160 | LSJ90/30 | 0.2-4.5m/min | 260 | 120 | 36×3.1×2.2 | 12.5 | |

| 20-63 | LSJ55/30 | 1-8m/min | 150-180 | 120 | 32×5.1×2.2 | 15.5 |