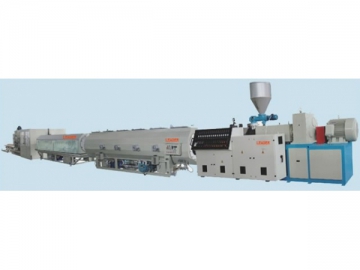

PVC Water Supply Pipe/Drainage Pipe Extrusion Line

Whether it is water supply pipes or drainage pipes that you want to produce, Leader Machinery can provide the suitable pipe extrusion line for your specific applications. The extruder of our PVC pipe extrusion line uses a two-stage screw for efficient extrusion. Coupled also with a unique flow diverter, this PVC pipe extrusion equipment is able to produce quality, stable extrusions at high speed while preventing the thermal decomposition of amorphous plastics.

The resultant PVC pipes can be used in building and construction for water supply and drainage applications. It is also commonly seen in industrial and agricultural water supply and drainage system applications. Another popular use is in the laying of cables.

Features

1. Vacuum calibrator of our PVC pipe extrusion line allows the hot pipe extrudate to be cooled rapidly and obtain the final pipe diameter.

2. Automatic temperature control system, pressure regulator, and vacuum control valve greatly enhance the pipe sizing and cooling performance as well as the production rate.

3. Multi-belt haul-off, also known as the caterpillar haul-off, uses a central motor drive to achieve synchronization of belts, which in turn protects the pipe roundness. Made of abrasion resistant materials, the haul-off belt does the job of consistently pulling the pipes at high speed.

4. Precision machined cutter is able to make flat, straight cuts into the pipes at high speed. A powerful suction device gathers up metal scraps after cutting, thereby making it easier for users to clean the cutter.

5. Automatic pipe expander comes with 2 heating furnaces to ensure pipe expansion quality and productivity.

| Model No. / Parameters | Pipe Diameter Range(mm) | Extruder Model No. | Production Rate (m/min) | Maximum Productivity (kg/h) | Installed Capacity (Kw) | Dimension (m) | Weight (t) |

| 16-63 | LSZ51/105 | 1-10 | 120 | 45 | 30×1.8×2 | 9 | |

| 75-200 | LSZ65/132 | 1.5-5 | 260 | 80 | 36×2×2 | 16 | |

| 160 -400 | LSZ80/156 | 0.5-1.5 | 400 | 115 | 37×2×2 | 23 | |

| 355 -630 | LSZ92/188 | 0.1-0.8 | 650 | 200 | 48×2.5×2.5 | 30.5 |