UPVC Double Pipe Extrusion Line

Leader Machinery is a specialist manufacturer of pipe extrusion equipment. Its UPVC double pipe extrusion line is made up of the LSZ51, LSZ105, LSZ65 or LSZ132 conical twin screw extruder, extrusion die, and other downstream components. Designed to produce 2 small-diameter PVC pipes at one time, the double pipe extrusion line is mainly used to produce electrical conduits.

Reasonable layout, dependable performance, and synchronization between the extruder motor and haul-off motor are the major benefits involved in the use of our UPVC double pipe extrusion line.

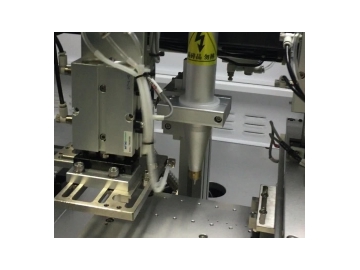

The main downstream components in the pipe production line are 2 vacuum sizing tanks wherein the accurate diameters of the two pipes are formed. Users can operate the 2 tanks separately, making adjustment to one pipe without affecting the other for avoiding wastes. The water level control comes with a sight glass through which operators would check if there is enough water inside the tank. The back and forth movements of the water level controller is powered by an electric motor. Available with a variable frequency drive, the belt haul-off uses a pneumatic clamp to get a firm hold of the pipe while cutting. The cutter automatically cuts the pipe to the required length. The shelf where finished pipes are stacked can automatically flip over to facilitate stacking.

PLC system and user-friendly human-machine interface are designed to meet customer specific needs.

Technical Specifications| Model No./ Parameters | Pipe Diameter Range (mm) | Extruder Model No. | Production Speed (m/min) | Production Capacity (Kg/h) | Installed Power (kw) |

| 20-63 | LSZ51/105 LSZ65/132 | 1-10 | 100-220 | 40-60 |