HDPE/ PVC Double Wall Corrugated Pipe Extrusion Line

This series of corrugated pipe extrusion line uses high-density polyethylene or PVC as raw plastics to produce large-size double walled pipes with corrugations on their exterior. Typical benefits involved in the use of twin wall pipes include light weight, great toughness, ease of installation, long service life, and resistance to high pressure.

Unique to the corrugated pipe are the parallel ridges and grooves on its exterior which help save construction material compared to a non-corrugated design. The pipe is easy to install and functions reliably, which is popularly used worldwide.

As a specialist manufacturer of pipe extrusion machinery, we are capable of designing and manufacturing advanced twin wall corrugated pipe extrusion line for global customers. The extrusion process is highly automated through the user-friendly human-machine interface. The resultant pipes are widely used in the drainage and ventilation system. Thus far, our Φ1000m and Φ1500mm corrugated pipe extrusion lines have been successfully launched in foreign markets and subsequently gained high praise from international customers.

Features

1. Conical twin-screw extruder is used to ensure high extrusion efficiency.

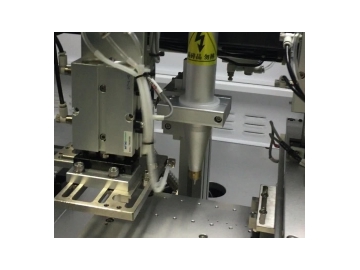

2. A combined extrusion die facilitates the extrusion of special helical pipe structure. Both the pipe exterior and interior have uniform thickness.

3. The corrugated pipe forming machine is comprised of movable upper and lower platforms for ease of operation. It also comes with the power failure protection device.

4. The state of the art gear reducer offers a high gear ratio. Automatic transmission allows for easy operation and convenient maintenance.

5. Combined cooling system provides both water cooling and air cooling functions. It allows the hot corrugated pipe to be effectively cooled without slowing down the overall speed of corrugated pipe extrusion line. Programmable lubrication system minimizes the mold wear.

6. Inline pipe expansion function ensures the thickness and roundness of expanded pipes. Operators do not need to manually operate the machine in order to get the pipe opening expanded. High automation improves production efficiency.

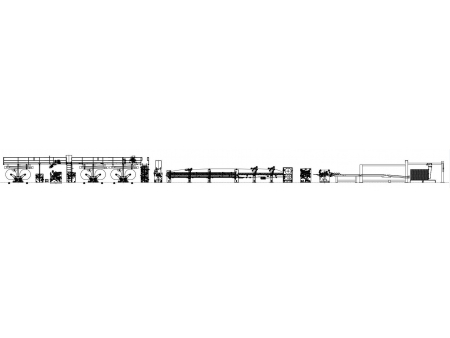

| Production Line Model No. | ||||

| Pipe Diameter (MM) | Φ110-250 | Φ200-500 | Φ250-1,000 | Φ800-1,500 |

| Cooling Mixer | SRL200/500 | SRL500/1600 | SRL500/1600 | SRL500/1600 |

| Conical Twin-Screw Extruder | SJSZ-80 | SJSZ-92 | SJSZ-92 | SJSZ-95 |

| Extrusion Die | Φ110, 125, 160, 200, 250 | Φ200, 250, 315, 400, 500 | Φ250, 315, 400, 500, 630, 800, 1000 | Φ800, 1000, 1200, 1500 |

| Corrugation Forming Machine | SBGC-250 | SBGC-500 | SBGC-1000 | SBGC-1500 |

| Spray Tank | SGL-250 | SGL-500 | SGL-1000 | SGL-1500 |

| Chip-Free Cutter or Ordinary Cutter | SGQ-250 | SGQ-500 | SGQ-1000 | SGQ-1500 |

| Automatic Pipe Expander | SKJ-500 | SKJ-500 | SKJ-1000 | SKJ-1500 |

| Production Capacity (kg/h) | 400 | 1,000 | 1,000 | 1,200 |

| Installed Power (KW) | 230 | 300 | 500 | 600 |

| Dimension (M) | 37×6×5.32 | 38×6×5.32 | 40×6×5.32 | 45×7.4×4.9 |

| Weight (T) | 30 | 50 | 80 | 110 |