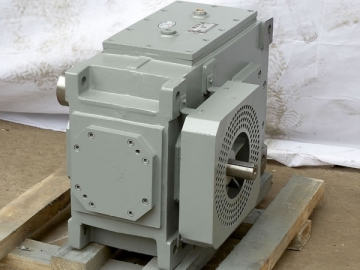

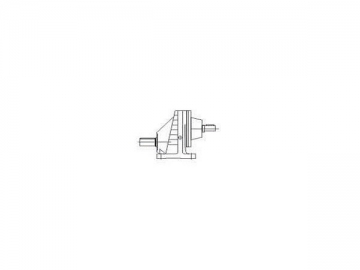

Parallel Shaft Gearbox

The parallel shaft gearbox is prominent with the advantage of quiet running. On each parallel shaft gear unit we conduct empty running test that lasts for not less than three hours. This progress involves the real-time monitoring of running noise and temperature rise. The noise level should be below 75DB, while the temperature should never be above 60 ℃. Any substandard product need to be re-commissioned until it meets standards.

Modernized gearbox solutions must be able to deal with a variety of negative factors, to achieve maximum efficiency and absolute reliability. To ensure high product availability and cost-saving maintenance, one must overcome these factors. Our gear motors come in helical geared motors, bevel geared motors and bevel-helical geared motors. They are suitable for horizontal or vertical mounting. The diverse options together with compact designs, maximizes the flexibility in product design.

Advantages

1. The parallel shaft gearbox adopts a design for universal application. It can be tailored to be an industry-specific variant according to customer demand.

2. The housing is universal to parallel shaft, perpendicular shaft, vertical, horizontal mounting options, with decreased parts types and increased specifications.

3. Deadening housing structure, large surface area, large fan. Cylindrical gears and helical-bevel gears are processed with advanced grinding technology. So, as a whole, the reducer has improved performance in heat dissipation, noise reduction, running reliability, and transmission power.

4. Output shaft with flange is designed to facilitate the installation of this high power gearbox.

5. FKM oil seal, is excellent in resistance against high temperature, aging, and wearing. It is more secure and durable in complex and hostile working environment.

6. Improved cooling fan and cooling coil design can more effectively cool the parallel shaft gearbox at running.

Application Examples

Belt conveyor drives

Bucket elevator drives

Agitator drives

Hoisting gear drives

Travelling gear drives

Paper machine drives

Dryer drives

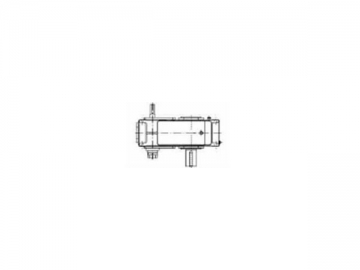

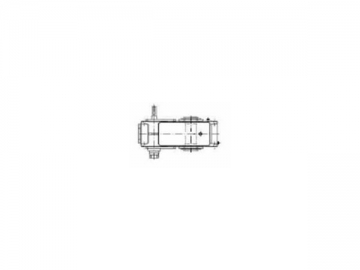

Mounting Options

Horizontally mounted, vertically mounted, or other mounting way as required.

The mounting flange and torque arm are parts of our standard supplies.

Noise Reduction

New design concepts were applied to improve the noise reduction of the gear units, by adopting: 1. noise-absorbing housing material; 2. exceptionally large contact ratios; 3. fine gear grinding process.

Thermal Conduction

The parallel shaft gearbox not only has high efficiency but also has favorable thermal conduction performance with enlarged housing surface area, large fan and new type of air conductive fan cover. The selection of appropriate gear unit should be based on a lower maximum oil temperature. In this way, the oil drain period will be lengthened to improve running reliability and save maintenance costs.

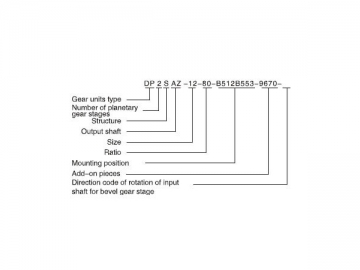

| Horizontal Mounting Position Parallel Shaft Helical Gear Unit Type: H1... .H2... .H3... .H4... 1-4 Stage Transmission, I N =1.25-450 | |

| WTH..SH: | H..HH |

H..DH: | H... HM,H... DM |

| Vertical Mounting Position Parallel Shaft Helical Gear Unit Types H2..V, H3..V, H4..V 2-4 stage Transmission, I N =6.3-450 | |

H..SV: | H... .HV. |