Automatic Handle Loop Inserting Machine for Cooking Oil Bottle

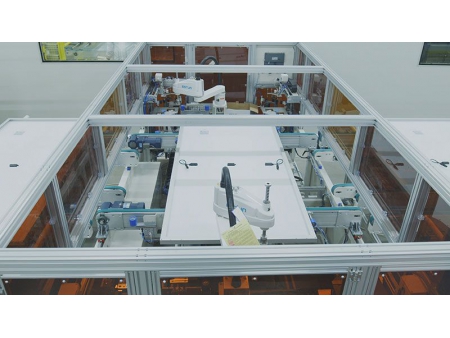

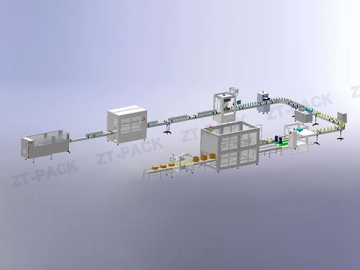

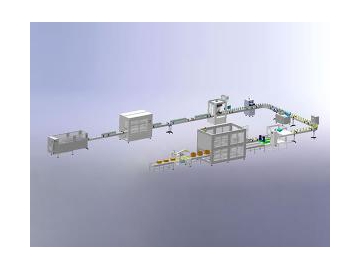

QZDAZTH-II automatic handle loop inserting machine is specialized designed 4L or 5L cooking oil bottle in square or round shape. This food packaging equipment is capable of inserting 5,000 to 7,000 handle loops every hour!

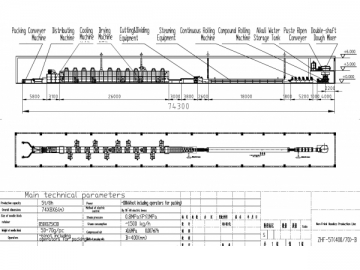

The entire plastic pull ring equipment includes centrifugal disc, conveyor, presser, lifting unit and power distribution cabinet. Automatic production process only requires staff to feed handle loops into lifting unit at regular interval. The oil bottle ring cap equipment will automatically press the handle loop on bottle cap.

Structure

1. Centrifugal disc is responsible for arranging handle loops into regular lines and transports them at certain speed to conveyor.

2. The conveyor embraces the impacts from the centrifugal disc and gently feeds handle loops to presser.

3. The presser compresses handle loops on oil bottle enclosure nice and slowly. Oil bottles go through the presser at constant speed with the aid of two flat belts. Therefore, no harm is done to trademarks on bottles.

4. Lifting unit in our automatic handle loop inserting machine is responsible for transporting unordered loops to the centrifugal disc.

Advantage

1. Harmless

The entire production process brings no damage to handle loops, oil bottle bodies, caps or trademarks. Noise generation is limited and level is controlled under 50 decibels.

2. Automation

The centrifugal disc is fitted with automatic jamming inspection system and controls the feeding speed of lifting unit to prevent overflow. Unqualified handle loops will be automatically discharged. Moreover, the conveyor instinctively stops feeding when fully charged, thus saving materials and energy.

3. Failure Alarm

This automatic handle loop inserting machine automatically triggers failure alarms on insufficient feeding and incomplete pressing, so that operatives can make timely remedy.

| Electric Motor | SEW electric motor and reduction gear |

| PLC | Mitsubishi FX1N 60MR |

| Electric Appliance | Schneider |

| Framework and Housing | Stainless steel |

| Sensor | Combination of models from USA, Germany,Korea, Japan and Taiwan |

| Pneumatic Component | AirTAC, SMC |