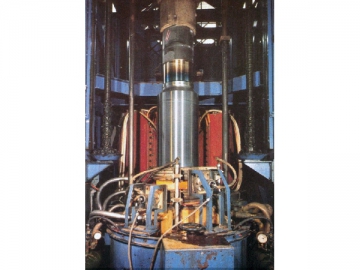

Vertical Induction Heating Machine

Our vertical induction heating machine covers the needs of all types of vertical hardening. The loading and unloading may either be done manually or automatically by robots. Usually, this universal vertical induction hardening machine is used for hardening long shaft or step shaft. It offers a solution for hardening workpieces which have complicated geometry, such as camshaft, drive shaft, etc.

We have a variety of models for the hardening of different workpieces. The machine comes in the following series. Welcome to contact us to know more about the parameters and processes.

1.

The HKVP500/2 vertical induction heating machine applies to the continuous induction hardening and integral hardening of small shafts and disk parts. The hardening is done with workpiece movement. The movement is controlled by Siemens CNC system. The PLC connection with medium-, high-frequency power supply achieves automatic quenching of various workpieces. This series comes in a variety of forms: single-shaft, double-shaft, single-station, double-station, etc.

Parameters of processable workpiece

1. Length: 10mm-500mm

2. Diameter: Ф5mm-Ф200mm

3. Maximum weight: 10kg

4. Maximum speed: 200mm/s

2.

The HKVC1500/2-2 is another multi-station induction hardening equipment that applies to the continuous quenching and integral quenching of medium and large shafts, as well as disk parts. This vertical induction heating machine comes in a variety of structural forms of single-shaft, double-shaft, single-station, multi-station, rotary and so on. Siemens CNC system is used to control the inductor movement and workpiece positioning. The PLC connection to medium-, high-frequency power supply achieves automatic quenching of various workpieces.

Parameters of processable workpiece

1. Length: 50mm-5000mm

2. Diameter: Ф20mm-Ф800mm

3. Maximum weight: 10000kg

4. Maximum speed of inductor movement: 500mm/s

5. Maximum length: 1500mm

3.

The HKVC5000 is an automatic induction hardening machine that adopts Siemens CNC system to control inductor movement and workpiece positioning. This vertical induction heating machine is capable of the continuous induction quenching and integral quenching of medium and large shafts, as well as disk parts. The machine comes in a variety of structural forms of single-shaft, double-shaft, single-station, multi-station, rotary, etc. The PLC connection to medium- and high-frequency power supply achieves automatic hardening of various workpieces.

Parameters of processable workpiece

1. Length: 50mm-5000mm

2. Diameter: Ф20mm-Ф800mm

3. Maximum weight: 10000kg

4. Maximum speed of inductor movement: 500mm/s

5. Maximum length: 5000mm

4.

The HKVP series of vertical induction heating machine is used for the quenching of all kinds of shafts, disks and other parts. Typical parts include camshaft, hub bearing, and small crankshaft.

Product description

1. Number of stations: 2

2. Movement: workpiece moves

3. Quenching length:10-500mm

4. Quenching diameter: Ф10-Ф100mm

5. Workpiece speed: 30-120rpm continuously adjustable

6. Repeat positioning accuracy: ± 0.1mm

7. Maximum workpiece weight: 10kg