Nitrogen Injection Fire Protection System for Transformer

The BPZM-MRD series nitrogen injection fire protection system is especially designed for oil-filled transformers, and two models, which are BPZM-40*2-I-MRD and BPZM-40*2-II-MRD are highly recommended.

We have 6 years of production experience for transformer protector, and this product has been successfully applied in TBEA (Tebian Electric Apparatus Stock Co., Ltd.), TWTB (Baoding Tianwei Group Tebian Electric Co., Ltd.) and TBEA Shenyang (Shenyang Transformer Co., Ltd.).

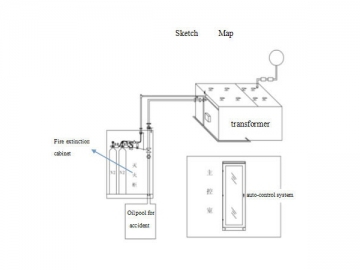

Working Principle

Our nitrogen injection system will be activated when the collected signals, which are released by gas relay and fire detector, meet preset requirements. If activated, the pressure relief valve (oil drain valve) will be opened in a short time to discharge some transformer oil so as to reduce pressure inside, and the shut-off valve, which is set between transformer and oil conservator, will be switched off due to sudden flow increase in order to stop oil in the conservator from flowing into the transformer.

After some delay time, the nitrogen injection fire protection system will continuously inject nitrogen gas into the transformer to cool down fault point inside the transformer. As a result, the temperature is reduced to below ignition point, and fire is put out. In addition, nitrogen shall be injected for 20 minutes at least to avoid re-combustion.

Feature

1. The transformer fire safety system uses PLC instead of conventional relays to cut down the failure rate of electrical devices, and it has a RS485 communication interface to facilitate data transmission, thus making it very convenient for the host computer to check our product's working status.

2. Due to the implementation of Schneider, ABB, Siemens and other famous brands' electrical components, this automatic transformer protection system is able to provide highly reliable performance.

Operating Condition

1. The nitrogen injection fire protection system should be installed at places without severe vibration or shock, and corrosive gas shall be avoided as well.

2. The fire detector, shut-off valve and fire protection cabinet can be installed outdoors, while the control panel shall be placed indoors.

3. Ambient temperature:

a. Outdoor device: -40℃~ 60℃

b. Indoor device: 5℃~ 30℃

4. Relative humidity:

a. Outdoor device: ≤95% at 20±5℃

b. Indoor device: ≤85% at 20±5℃

5. Power supply: DC220V or DC110V

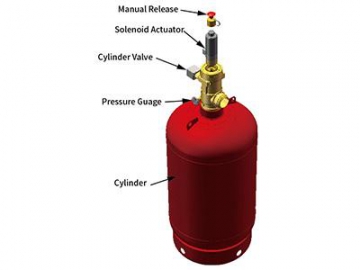

Technical Data| Transformer capacity (MVA) | ≤50 | 50-360 | >360 |

| Nitrogen bottle volume (L) | 40 | 40 | 63 |

| Nitrogen bottle quantity | 1 | 2 | 2 |

| Initial nitrogen pressure (MPa) | 15 | 15 | 15 |

| Nitrogen pressure after injection (MPa) | 0.6 | 0.6 | 0.6 |

| Nitrogen volume after injection (L) | 1000 | 2000 | 3150 |

| Continuous nitrogen injection time (min) | 31 | 31 | 31 |

| Nitrogen injection rate at valve outlet (L/min) | 32.25 | 64.51 | 101.61 |

| Nitrogen speed in injection pipe (m/s) | 1.095 | 2.19 | 3.45 |

| Nitrogen injection hole number | 2 | 4 | 6 |

| Nitrogen flow rate in injection hole (L/min) | 16.13 | 16.13 | 16.94 |

Ordering Instruction

The following information is needed when ordering our nitrogen injection fire protection system.

1. Layout, contact information of transformer manufacturer and design house

2. Other special requirements

Service

Our product comes with schematics, wiring diagrams and installation guide, while on-site installation and testing services are also available.