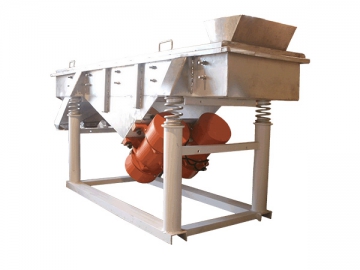

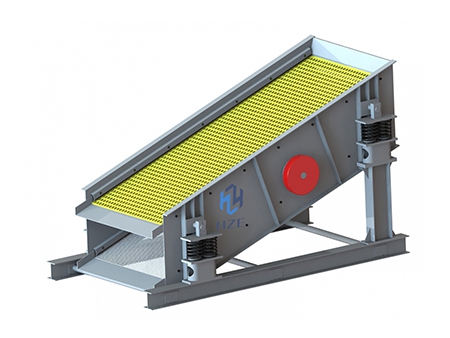

Circular Vibrating Screen

Introduction

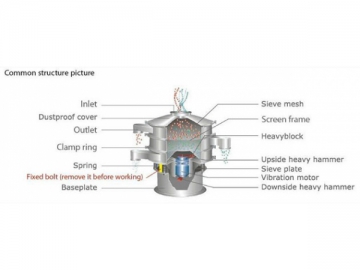

Our XZS series circular vibrating screen is a high efficiency screening machine manufactured with advanced technologies and designs on the basis of our previous products, S49 series screens. The XZS vibrating screen features eco-friendliness, convenient sifter changing process, low working noise, enclosed structure, high safety and efficiency. It can be used for screening and filtering granular, powdery, and serous materials.

Principle

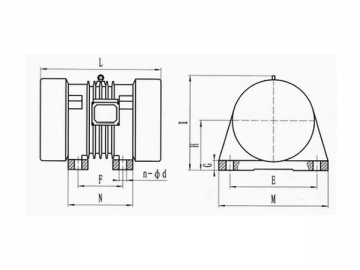

Our circular vibrating screen, as a piece of powdery material screening equipment, uses horizontal vibration motor or special vibration exciter as its vibration source. The horizontal vibration motor and vibration exciter have an eccentric block at both their upper and lower sides. The eccentric blocks can generate a three-dimensional movement in horizontal, vertical, and inclined directions. By adjusting the phase angles of the upper and lower eccentric blocks, the material on the screen can change the movement locus, achieving suitable screening performance.

Feature

1. The screening precision of our circular vibrating screen is excellent, and the blocking rate of the screen is less than 10% in average.

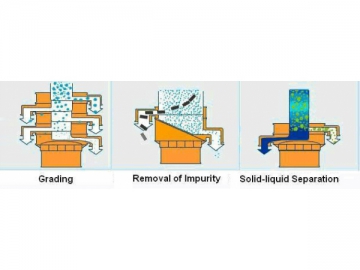

2. The movement locus and vibration amplitude are both adjustable. Any granular, powdery, and serous materials can be roughly screened, finely screened, or just filtered according to the material applications.

3. The screening machine is 500-2000mm in diameter, and the overall size is quite small. Wheels can be mounted on it for convenient moving.

4. The screen frame of the circular vibrating screen is specially designed. It takes only 5-10 min for the screen changing. The stainless steel wire woven net is easy to clean and operate, while the life span is quite long.

5. Completely enclosed structure is adopted so the particulate matter pollution in the air is quite limited.

6. The discharging outlet can be rotated at 360°, facilitating the installation of matching equipment.

7. The energy consumption of our circular vibrating screen is small, while the noise could reach as low as 73-80 dB.

8. During the operation, if short circuit, phase loss or unstable voltage occurred, the motor will automatically cut off the power supply and stop working. Thus the motor damage can be reduced to an extremely low level.

9. The IP rating of the motor is IP65, which means the motor is dustproof, and waterproof. Besides, the motor is also heatproof and oil resistant.

Application

1. Food industry

Our circular vibrating screen can be used for processing starch powder, sugar powder, salt, rice flour, milk powder, soy bean milk, sauce, fruit juice, condiment, and so on.

2. Chemical industry

This rotary vibrating sieve is widely used for handling resin powder, paint, industrial chemicals, detergent powder, cosmetic, Chinese medicine powder.

3. Metallurgy industry

In metal processing industry, this circular vibrating screen can sift alluminium powder, lead powder, copper powder, alloy metal powder, electrode powder, manganese dioxide powder, electrolytic copper powder, abrasive powder, high temperature resistant material, Kaolin, limestone, dolomite, alumina, calcium carbonate, quartz sand, and so on.

4. Pollution abatement

Our sifting machine is also suitable for treating waste oil, sewage, accessory ingredient, and activated carbon.

Parameter

Parameter| Model | | | | | | | | |

| Diameter (mm) | 500 | 600 | 800 | 970 | 1170 | 1470 | 1770 | 1970 |

| Layer | 1-5 | |||||||

| Sieve Size (mm) | 0.025-20 | |||||||

| Rotary Speed (rpm) | 1440 | |||||||

| Power (kW) | 0.12 | 0.18 | 0.36 | 0.5 | 1.1 | 1.1 | 1.5 | 1.5 |

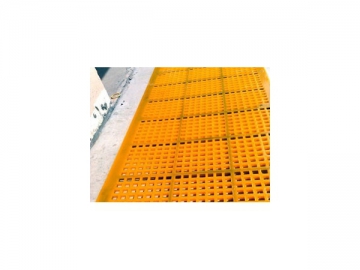

Detail picture

1. Simulated diagram of screening 2. Layer number

2. Layer number 3. Material

3. Material- Stainless steel (contacting

with material) - Stainless steel

- Carbon steel

- Vibration motor

- Screen frame

- Fastening ring

- Silicone sealing element

- Bouncing ball

- Spring

- Sieve

- Tools

- Rubber sealing element

Optional configuration and service

1. A wide range of voltages are supported, including 110V, 220V, 240V, 380V, 415V, 450V and 550V.

2. Both 50Hz and 60Hz power can be used.

3. The wheel, viewing hole, and frequency converter are optional.

4. The OEM service is available for our circular vibrating screen.